Is your device showing all indicator lights but still unable to start when you turn the key? Is this a starter motor issue? How do you diagnose and resolve it? This article will explain the working principle of the bad starter symptoms, fault warning signals, and how to fix starter problems.

What Is a Starter and How Does It Work?

A starter is a compact electric motor designed to turn your engine’s crankshaft during ignition. In heavy equipment, this motor uses direct current from the battery to spin the engine until combustion begins. The starter solenoid acts as the gatekeeper, channeling battery voltage into the motor when you push the start switch.

Inside the unit, the pinion gear engages with the flywheel ring gear, transferring torque to create rotation. Once the engine fires, the gear retracts automatically. Because off-road machinery operates under harsh conditions—dust, vibration, and heavy loads—the starter must supply consistent torque and survive repeated cold starts.

Below is a simplified overview:

| Component | Function | Failure Effect |

|---|---|---|

| Solenoid | Transfers electrical current to the motor | Clicking sound, no crank |

| Armature | Converts electricity to motion | Weak or no rotation |

| Pinion Gear | Engages the engine flywheel | Grinding noise |

| Starter Relay | Controls current flow | Total silence when starting |

When any of these fail, your machine won’t crank—and that’s when bad starter symptoms start to appear.

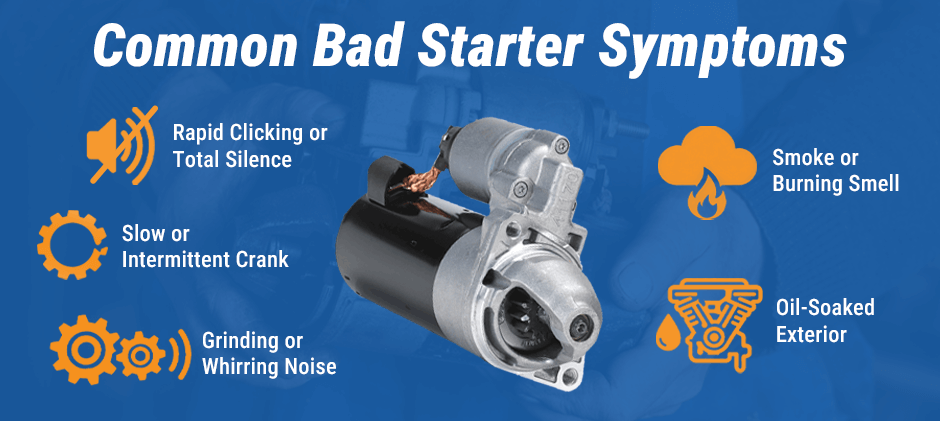

Common Bad Starter Symptoms

Heavy equipment doesn’t signal a bad starter as clearly as road vehicles; noises are often masked by larger systems. Still, the symptoms are unmistakable once you know what to watch for.

1. Rapid Clicking or Total Silence

If you hear multiple clicks—or nothing at all—when you turn the key, the solenoid might be engaging but not transferring power. This is one of the earliest bad starter symptoms technicians detect. It often suggests worn contacts or corroded connections within the starter circuit.

2. Slow or Intermittent Crank

When your loader or excavator engine struggles to turn over, the starter’s torque output may be down. High resistance, worn brushes, or internal bearing drag can prevent full-speed cranking. You might notice this more in cold weather when the oil is thicker.

3. Grinding or Whirring Noise

A high-pitched whirring suggests the pinion gear spins freely without engaging the flywheel. Alternatively, grinding means the gear teeth aren’t meshing properly—either from wear or misalignment. Continue starting like this, and you risk damaging the flywheel ring gear as well.

4. Smoke or Burning Smell

Repeated start attempts with a failing starter can overheat its wiring. You may see smoke near the housing or detect a burnt solvent smell—classic bad starter symptoms caused by electrical overload.

5. Oil-Soaked Exterior

Oil contamination is common in field machinery. Leaks from the crankcase or hydraulics can coat the starter, shorting circuits, and attracting abrasive dust. Once oil-soaked, the starter’s insulation breaks down quickly, leading to a complete failure.

What Causes Starter Problems?

Starter issues rarely appear overnight. They usually result from environmental stress or neglect. Below are some frequent culprits:

- Loose Wiring or Corroded Terminals: Weak electrical flow prevents full motor activation.

- Battery Problems: A weak or sulfated battery forces the starter to draw extreme current, accelerating wear.

- Fluid Contamination: Engine oil, coolant, or hydraulic fluid infiltration shortens electrical life.

- Overcranking: Holding the key too long when the engine won’t start, overheats coils and brushes.

- Aging Components: Starters experience thousands of duty cycles; mechanical fatigue is inevitable in older machines.

Equipment Won’t Start? Starter Troubleshooting Tips

Before assuming your engine has major issues, isolate whether the bad starter symptoms come from the electrical system, the fuel system, or the starter motor itself.

1. Check Power Supply:

Use a multimeter—voltage should read above 12.6V. Drop below 12.3V? Charge or replace the battery first.

2. Inspect Cables and Grounds:

Loose ground straps or corroded terminals mimic starter failure. Clean and tighten before replacing anything.

3. Bypass Test:

Directly feed 12V to the solenoid terminal. If the motor spins, the issue is with your ignition circuit—not the starter.

4. Listen for Mechanical Engagement:

No sound from the pinion gear often means an internal solenoid malfunction. A single click followed by silence signals electrical failure.

5. Avoid Continuous Cranking:

Crank durations should stay under 10 seconds with 60-second rests. Overuse overheats windings.

When diagnostics confirm mechanical failure, replacement is the most reliable option. At this point, consider sourcing a durable starter motor for off-road equipment. FridayParts offers a broad range of aftermarket options covering Kubota, Yanmar, Komatsu, Bobcat, and many more, ensuring compatibility and long service life even in severe field environments.

How to Prevent Starter Failure?

Maintaining a reliable start system isn’t complicated—it’s about consistency and inspection. Here’s what works:

- Keep Electrical Terminals Clean: Dirt and rust create voltage drops. Apply protective grease regularly.

- Monitor Engine Seals: Prevent fluid leaks before they soak your starter.

- Test Battery Health: Replace weak batteries before winter; cold cranking demands more current.

- Use Equipment Regularly: Starters in idle machines corrode faster due to moisture accumulation.

- Schedule Preventive Checks: Add starter torque and voltage drop testing to your monthly maintenance checklist.

Tip: Record starting performance after heavy rain or mud operations—any change in sound or speed may indicate early deterioration.

FAQs

1. What are the most visible signs of a bad starter in off-road machinery?

Slow cranking, clicking without turnover, or complete silence. Smoke or burnt smells may also appear if electrical coils are overheating.

2. Can I jump-start heavy equipment with a failing starter?

Jump-starting only helps if the battery is low. If the starter motor itself is defective, a jump will not engage the engine.

3. How long should a starter last on construction equipment?

Typically, between 3,000 and 5,000 start cycles, depending on operating conditions and maintenance quality.

4. Are bad batteries often mistaken for bad starters?

Yes. A weak battery can mimic nearly all bad starter symptoms. Always test the voltage before replacing the starter.

5. Can oil leaks affect the starter?

Absolutely. Leaking oil shortens component life and causes short circuits. Repair leaks immediately.

Replace Before It Fails

When your excavator or loader is not willing to crank, the time spent stopping work is costing even more than the fixing itself. Changing the old and tired unit earlier can stop the loss of working efficiency. FridayParts is providing high-quality aftermarket starter motors for almost all big off-road brands at a price that is friendly, also supported by the delivery you can trust and the experts who can help. You can look through the FridayParts Starter Motor Inventory today to make your heavy machine always ready for each start.