For owners and restorers of off-road agricultural machinery, knowing the detailed differences between the Ford 9N, 2N, and 8N tractors is essential. These machines may look similar, but mechanical, hydraulic, and functional variations significantly separate them in terms of operation and maintenance. This guide provides everything you need to accurately identify each model, understand its engineering evolution, and source the right Ford tractor parts for efficient restoration or field service.

The Ford N‑Series Legacy (Short Overview)

Ford’s N-Series tractors changed the course of small-scale farming forever. Beginning with the 9N in 1939, the series introduced hydraulics, ease of maintenance, and affordability, allowing small farms to mechanize their operations.

The biggest leap was the introduction of Harry Ferguson’s three-point hitch, integrating tractor and implement as one system — a revolutionary concept that shaped every tractor design afterward.

With that foundation, let’s explore each model in order.

-

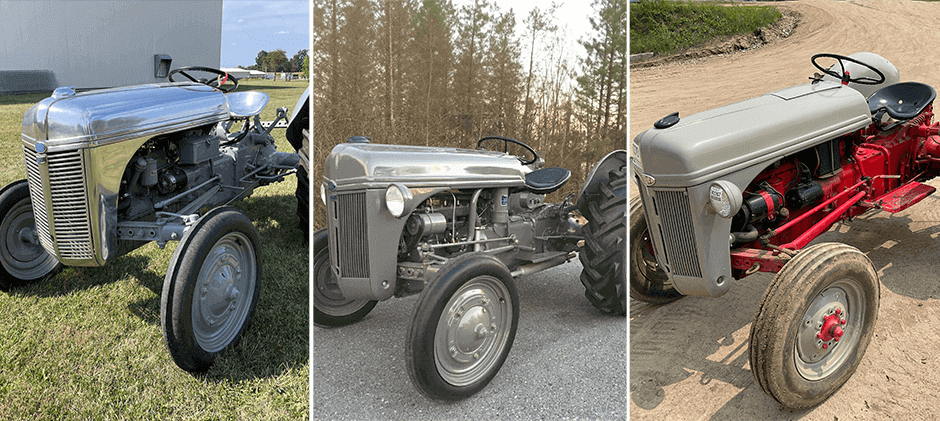

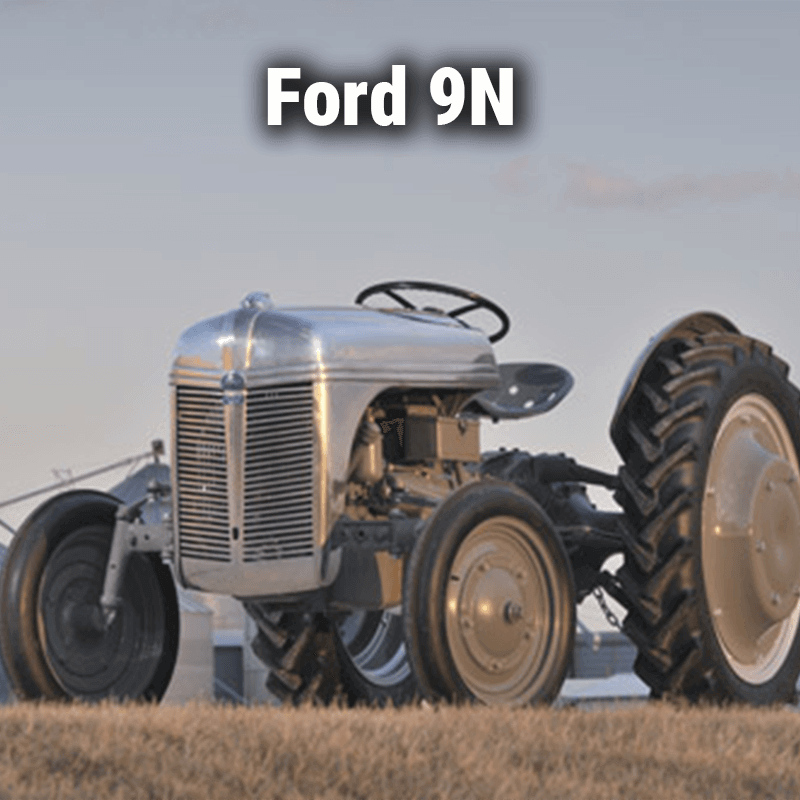

Identifying Features

- Aluminum hood and grille (on early 1939 units only).

- Six‑lug rear wheel pattern.

- Split brake pedals – one on each side of the transmission.

- Front‑mount distributor on the engine.

- Steel spoke steering wheel and low instrument cluster.

-

Field Performance

Operators praised the 9N for its reliability but noted the 3‑speed transmission could feel limited in hilly or varied‑load work. Power was sufficient for plowing small fields, hauling, and scraping tasks, but traction could be challenging in clay or loose soil conditions — something Ford addressed later.

Ford 2N (1942 – 1947): A Wartime Workhorse

With America fully engaged in World War II, Ford faced strict material rationing. The 2N emerged as a practical wartime evolution of the 9N to comply with production constraints yet sustain the agricultural sector.

-

Key Engineering Highlights

- Steel Wheels and Hand Cranks: Some 2Ns omitted rubber tires and batteries to conserve critical materials.

- New Generator & Coil System: Modified electrical design for stability under reduced supply components.

- Tubular radius arms after mid‑1944 – a quick visual identifier.

- Dipstick relocated to the side inspection plate for easier oil checks.

- Same 3‑speed gearbox and draft control, continuing the functional template of the 9N.

-

Operational Insights

Mechanically, the 2N remained almost identical to the 9N. However, subtle improvements to axle strength, oil‑seal design, and electrical durability meant more robust field performance. As many 2Ns remained in post‑war service, durability became their hallmark.

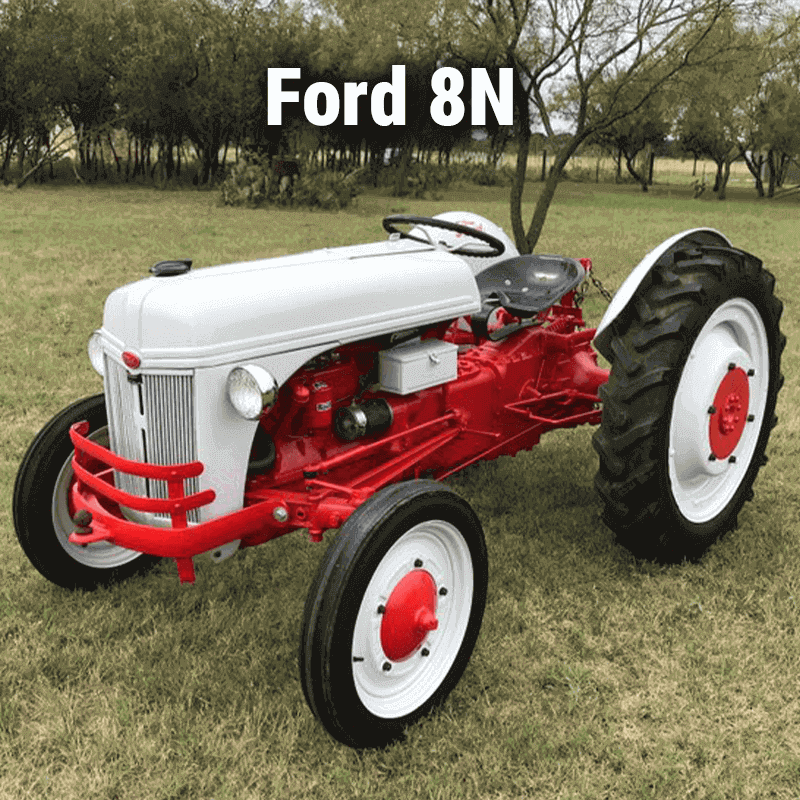

Ford 8N (1947 – 1952): The Defining Upgrade

By 1947, economic recovery allowed Ford to redesign the N-Series entirely. The Ford 8N was mechanically superior, ergonomically improved, and visually distinct. It became the best-selling agricultural tractor of its era.

-

Core Upgrades

- 4‑Speed Transmission: An extra gear for better range — ideal for tillage and transport.

- Position Control Lever: Operators could raise implements to precise heights, not just up or down.

- Both Brake Pedals on the Right: Simpler operation, especially for mowing and loader use.

- Updated Steering Box: Reduced play and input vibration.

- Red engine and gray hood paint: A new “red‑belly” fashion identifier.

- Optional Proofmeter (on 1951‑52 versions): Measuring engine hours and rpm helped maintenance planning.

-

Field Performance

The combination of a faster gearbox and refined hydraulics made the 8N far more versatile off‑road. It handled larger mowers, tillers, and cultivators while remaining lightweight. The side‑mount distributor on later models made servicing safer and more straightforward.

Difference Between a 9N, 2N, and 8N (In‑Depth Section)

At a glance, all three N-Series tractors share similar frames and dimensions, yet they differ greatly in functionality. Identifying the right model is crucial when ordering replacement parts or planning upgrades.

1. Transmission and Powertrain

- 9N & 2N: 3 forward gears + reverse. Limited speed control makes fine-tuned ground speed difficult.

- 8N: 4 forward gears + reverse — the added gear gives smoother plowing and more economical fuel use.

Many collectors consider the 4-speed 8N gear set one of the most serviceable designs in post-war ag machinery.

2. Hydraulics and Hitch Control

- The 9N and 2N offered draft control only — the implement reacted to soil pressure alone.

- The 8N introduced position control, activated via a small lever under the seat, allowing mid‑height lift positions for road grading, light blading, or mower work.

Position control was a game-changer — for the first time, an operator could ‘feather’ a grader blade instead of dropping it to the ground.

4. Wheel and Axle Design

- 9N / 2N: Flat rear hubs with 6 lugs set far out from the center.

- 8N: Dished rear wheel design with eight closely set lugs.

These visual differences make model recognition easy, even from a distance.

5. Electrical System and Distributor Position

- 9N & 2N: Front-mount distributor beneath the fan — tricky to service, especially in mud and dust.

- 8N (1951 onward): Side-mount distributor and 12-volt-ready design — a major step forward in serviceability.

6. Styling and Color Cues

The paint scheme is the fastest identifier:

- Gray for 9N and 2N.

- Red engine with light-gray hood for 8N.

Beware: many restored 9Ns wear red paint by mistake.

7. Serial Numbers and Markings

All serial numbers are stamped on the engine block’s left front. Formats overlap:

- 9N#### – could mean a 9N or early 2N.

- 8N#### – always an 8N.

Owners can verify precise years using N-Series serial decoding charts or apps.

8. Operator Experience and Performance

The 8N feels like an entirely different machine:

- Smoother clutch and steering action.

- More responsive hydraulics.

- Slightly higher PTO horsepower (27 vs 23 HP).

- Narrower turning radius for off-road maneuvering.

Meanwhile, the 9N and 2N are appreciated for simplicity — fewer moving parts, excellent fuel economy, and timeless durability.

9. Restorers’ Perspective

Collectors often find “hybrid” units: tractors rebuilt over decades with mixed features — an 8N transmission in a 9N frame, or 2N radius arms on an 8N axle. These mixups highlight how interchangeable N-Series components are, but also why you should double-check before ordering replacement parts.

The N-Series by the Numbers

| Model | Years Built | Units Produced | Approx. Price (New) | PTO Horsepower |

|---|---|---|---|---|

| 9N | 1939 – 1942 | ≈ 99,000 | $585 | ~ 23 HP |

| 2N | 1942 – 1947 | ≈ 90,000 | $1,120 | ~ 23 HP |

| 8N | 1947 – 1952 | ≈ 524,000 | $1,404 | ~ 23 HP |

Maintaining and Upgrading Your N-Series

Keeping an N-Series operational 70+ years later relies on genuine-fit replacement parts. Components like ignition kits, thermostats, oil pressure gauges, and hydraulic seals are readily available from trusted aftermarket sources like Ford tractor parts.

Those restoring classic 8Ns or customizing working units can find specialized assemblies, including fuel sediment bowls, radiator hoses, and distributor kits in the Ford 8N tractor parts catalog — each one engineered for precise fit and long field life.

Conclusion

From the 9N’s ingenious simplicity to the 8N’s refined control and power, the Ford N-Series defined mid-century off-road machinery design. Today, these tractors still deliver practical value and heritage. To keep them working for decades to come, choose high-quality, cost-effective aftermarket parts available through Ford tractor parts. Whether you’re rebuilding a 9N engine or fine-tuning a proofmeter on an 8N, FridayParts ensures compatibility, fast delivery, and lasting performance.