Why does the engine reduce its own power? Isn’t that strange? Actually, this method aims to protect your investment. This guide will tell you what engine power reduced means on your machine’s dashboard and how to fix it.

What Does “Engine Power Reduced” Actually Mean?

When your display says “Reduced Engine Power” or “Engine Power Is Reduced”, your machine’s Engine Control Module (ECM) has detected a serious problem in one of its critical systems.

To prevent costly damage to the engine, emissions system, or hydraulics, it automatically limits output. This is called “limp mode” or “fail‑safe mode.”

In simple terms:

- The ECM is restricting performance to protect your engine until you fix the problem.

- You may still be able to move your machine, but power is reduced to help you reach a safe area.

Key takeaway: Reduced Engine Power = A built‑in safety mode to protect your equipment, not a total failure.

Common Causes of Reduced Engine Power

Although similar to what happens in cars, off‑road machinery experiences unique stresses like dust, vibration, and heavy loads. Here are the main causes:

Fuel System Issues

If your diesel engine isn’t getting enough fuel, performance drops immediately. Common culprits include clogged fuel filters, which are frequent on dusty job sites and restrict fuel flow; failing fuel pumps, where a weak lift or injection pump can’t maintain the required pressure; and dirty or faulty injectors that cause unbalanced or poor fuel delivery.

Emissions and Aftertreatment Problems

Modern Tier 4 Final engines rely on complex emissions systems. A clogged DPF (Diesel Particulate Filter) full of soot will cause the ECM to limit engine output. Similarly, a DEF / SCR system fault, often due to low-quality DEF or a bad sensor, can force the system to derate power. A stuck EGR valve, typically jammed by excess soot, will also affect air-fuel ratios and trigger a power reduction.

Faulty Sensors

Even one bad sensor reading can trigger a reduced power mode. This includes a faulty throttle position or accelerator pedal sensor sending incorrect input to the ECM, incorrect readings from pressure sensors (MAP, fuel rail, oil pressure) creating safety limits, or a false “overheat” signal from temperature sensors (coolant, EGT) leading the ECM to cut power immediately.

Air Intake and Turbocharger Problems

Engines need clean air—and pressure—to create power. A clogged air filter from dust buildup restricts airflow, causing smoke and power loss. Turbocharger or boost leaks, resulting from loose hoses or actuator faults, reduce boost pressure and trigger a derate.

Electrical and Hydraulic System Faults

Electronic controls and hydraulics are tightly integrated in modern machines. Damaged wiring or connectors can cause poor sensor signals due to constant vibration. Low voltage or weak batteries can lead to ECM miscommunication and false codes. Additionally, if the ECM senses hydraulic pressure or temperature issues, it automatically reduces engine power to avoid damage to pumps and seals.

How to Fix the “Engine Power Reduced” Warning

Here’s your step-by-step plan to safely restore full engine power.

Step 1: Move to Safety

If possible, slowly move the machine to a safe, stable area and switch off the engine.

Step 2: Read Diagnostic Trouble Codes (DTCs)

Use the correct diagnostic scanner for your machine’s brand (Caterpillar, Komatsu, John Deere, Volvo, etc.). The codes will identify where the problem lies.

A standard automotive reader (OBD‑II) won’t work on heavy equipment.

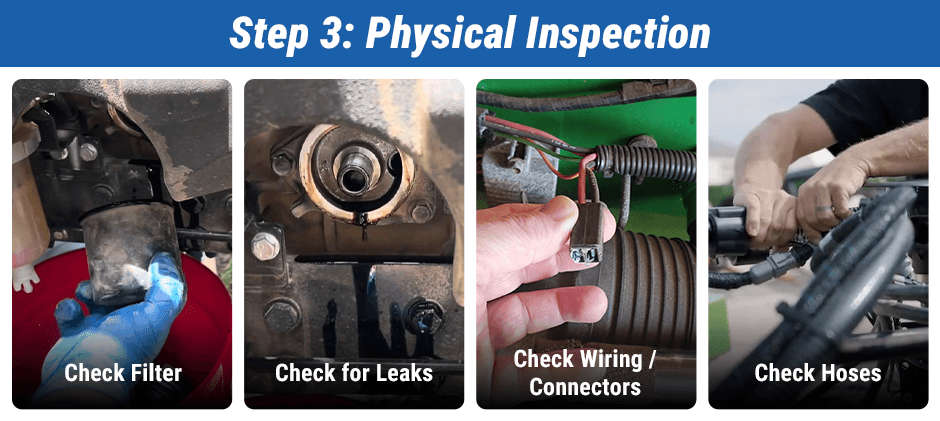

Step 3: Inspect Key Components

With the DTC identified, begin a physical inspection. Check fuel and air filters for blockages, look for damaged wires or loose plugs, inspect for leaks of fuel, coolant, or hydraulic oil, and check turbo and intake hoses for any cracks or loose connections.

Step 4: Research Technical Bulletins

Manufacturers sometimes publish service bulletins for known faults. A quick lookup of your model + DTC can reveal a proven fix.

Step 5: Replace the Faulty Part

Once identified, replace the bad component. Use quality aftermarket or OEM‑spec parts for reliability and long life.

Call a qualified technician for complex jobs like ECM replacement, injector coding, or any emissions system fault that requires proprietary software (such as a forced DPF regeneration or SCR system diagnostics). Simpler component swaps, like a faulty sensor, may be manageable if you have the right tools and experience.

FAQs

Q1: Can I keep working with the “Reduced Engine Power” light on?

No. It’s a safety‑limiting mode. Driving or operating in this state risks engine or emissions damage.

Q2: How do I reset the “Engine Power Reduced” light?

You can’t just reset it—the ECM clears the warning automatically once you fix and erase the fault codes.

Q3: What causes reduced engine power after a fluid top‑up?

This often happens for two reasons: 1) Contamination during refilling, where dirt or water enters the tank. 2) The system needs to be reset. For instance, if the DEF tank were run empty, the SCR system may need several engine cycles to verify the new fluid’s quality before it clears the derate. Ensure fluids are clean and at proper levels.

Q4: Can low hydraulic pressure cause reduced engine power?

Yes, it can. If hydraulic temperature is too high or pressure is overloaded, the ECM reduces engine power to protect the hydraulic pumps and seals. Conversely, if hydraulic pressure is too low, it could signal a major leak or low fluid level. The ECM will then derate the engine to prevent the hydraulic pump from running dry and suffering catastrophic failure.

How to Prevent Reduced Engine Power Warnings

- Use clean fluids and filters: Replace fuel and air filters regularly.

- Inspect wiring harnesses: Protect them from vibration damage.

- Monitor DEF quality: Contaminated fluid triggers false emissions faults.

- Warm up properly: Giving diesel engines time to reach operating temperature reduces soot buildup.

Get Back to Full Power with FridayParts

A reduced engine power warning doesn’t have to mean days of lost work. With accurate diagnosis and quality replacement parts, you can restore full performance quickly.

At FridayParts, we supply:

- OEM‑standard and aftermarket sensors, filters, pumps, and converters for top brands.

- Fast global shipping to minimize downtime.

- Professional support to help you find the correct part for any model.

Tip: Order critical parts in advance—having spares on-site can save hours when that “Engine Power Reduced” message appears.

Final Thoughts

In 2025 and beyond, with Tier 4 Final / Stage V emissions standards fully in place, aftertreatment systems are a leading cause of power reduction. Understanding these systems is more critical than ever. Acting fast and following the right diagnostic steps prevents small issues from becoming expensive failures.

At FridayParts, we do more than just ship parts. We provide the knowledge you need to make the right diagnosis and the quality components to ensure your repair lasts. With our extensive inventory of OEM-standard sensors, filters, starter motors, and pumps, you can turn an ‘Engine Power Reduced’ crisis into a quick, cost-effective fix.