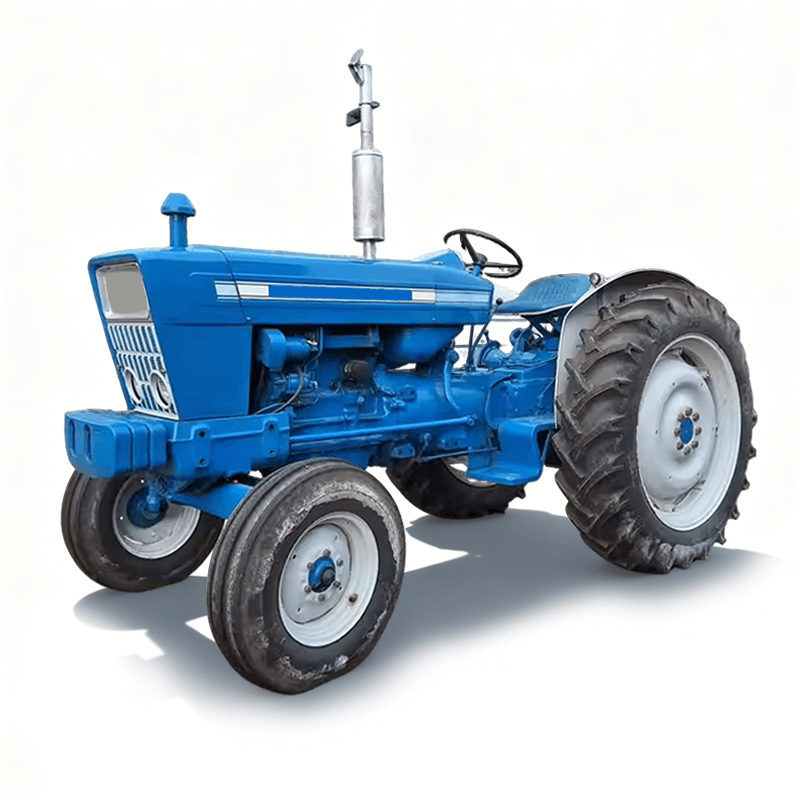

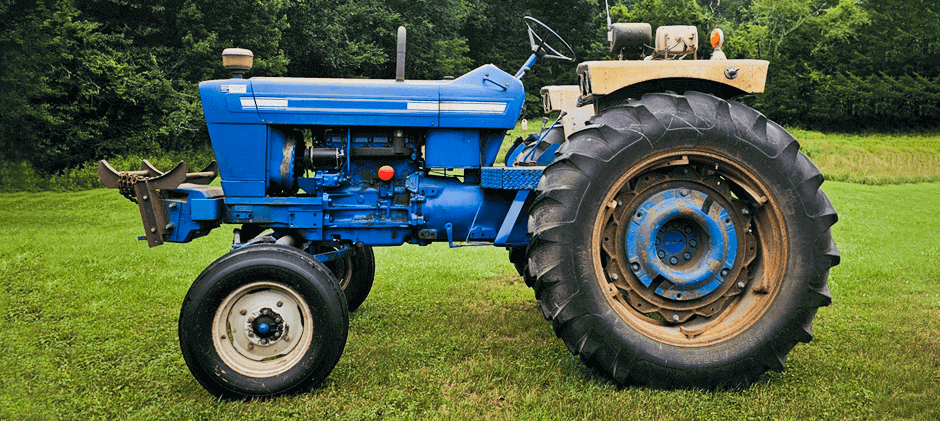

For many users operating in off-highway conditions—such as logging, livestock management, or heavy tillage—the Ford 5000 stands out for its durability and high-torque diesel engine configuration. Today, we’ll delve deeper into this tractor, detailing its key specifications, serial number, maintenance tips, and frequently asked questions from the Ford 5000 forum community to help you understand this tractor.

About the Ford 5000 Tractor

The Ford 5000 tractor marked a milestone in the evolution of mid-range agricultural and off-road machinery. Produced from the mid-1960s through the mid-1970s, it represented a leap in mechanical simplicity, reliability, and field strength that remains respected even half a century later.

Here are the defining strengths of the Ford 5000:

- High-Torque Engines: The Ford 5000 used a 4.2L, four-cylinder engine in both diesel and gasoline versions. The engine was renowned for its exceptional endurance, producing approximately 60–70 PTO horsepower — a substantial figure for its size and era.

- Versatile Transmission Setup: Operators could select from an 8-speed manual or 10-speed Select-O-Speed (early powershift). Later “Dual Power” models effectively doubled gear ranges.

- Dependable Hydraulics: The open-center hydraulic system with 2500 psi made loader use and 3-point implement control seamless and responsive.

- Balanced Weight Distribution: Ideal for off-road traction, allowing excellent pulling power on slopes and loose soils.

- Ease of Service: The engine itself formed part of the frame, minimizing stress points and simplifying maintenance.

Ford 5000 Tractor Key Specifications

Engine

| Ford gasoline 4-cylinder liquid-cooled |

– |

|---|---|

| Displacement | 233 ci 3.8 L |

| Bore/Stroke | 4.20×4.20 inches 107 x 107 mm |

| Power | 69 hp 51.5 kW |

| Compression | 8.0:1 |

| Rated RPM | 2100 |

| Firing order | 1-3-4-2 |

| Starter volts | 12 |

| Coolant capacity | 15.3 qts 14.5 L |

| Intake valve clearance | 0.015 inches* 0.381 mm |

| Exhaust valve clearance | 0.018 inches* 0.457 mm |

Transmission

| Transmission options | 8-speed

10-speed full power shift 16-speed partial power shift |

|---|---|

| Transmission | sliding gear |

| Gears | 8 forward and 2 reverse |

| Oil capacity | 10.8 qts 10.2 L |

| Oil type | M-4864-A |

Dimensions

| GP Wheelbase | 87.5 inches 222 cm |

|---|---|

| Row-crop Wheelbase | 96 inches 243 cm |

| GP Length | 141.6 inches 359 cm |

| Row-crop Length | 149 inches 378 cm |

| Width | 68.5 inches 173 cm |

| Ground clearance | 14.25 inches 36 cm |

| GP Front tread | 52 to 80 inches 132 to 203 cm |

| Row-crop Front tread | 56 to 88 inches 142 to 223 cm |

| Rear tread | 56 to 80 inches 142 to 203 cm |

Source from: www.tractordata.com

Serial Number by Year

Locating and understanding your serial number is fundamental for accurate maintenance and part identification. The serial number is stamped on a flat pad behind the starter motor on the left-hand side of the engine block.

| Year | Serial Number Range |

|---|---|

| 1965 | C100001 – C124599 |

| 1966 | C124600 – C148999 |

| 1967 | C149000 – C172999 |

| 1968 | C173000 – C196999 |

| 1969 | C197000 – C220999 |

| 1970 | C221000 – C244999 |

| 1971 | C245000 – C268999 |

| 1972 | C269000 – C292999 |

| 1973 | C293000 – C316999 |

| 1974 | C317000 and up |

When sourcing replacement components, matching your serial number range ensures compatibility, particularly if your machine falls around early-production years, where component changes often occurred mid-run.

Maintenance Tips for Ford 5000

To ensure longevity in off-road conditions, proactive care is essential. Dust, uneven surfaces, and variable loads expose the machine to mechanical wear much faster than in light-duty farm use.

Routine Maintenance Schedule

| Task | Interval |

|---|---|

| Engine Oil & Filter | 100 hours annually |

| Fuel Filter | 200 hours |

| Air Filter | Monthly or more often in dusty environments |

| Coolant Flush | Every 2 years |

| Hydraulic Fluid & Filter | Every 400 hours |

| Grease Fittings & Joints | Weekly or before heavy fieldwork |

Maintenance Insights:

- Always use OEM-grade hydraulic and transmission fluids to retain correct PSI levels for the lift system.

- Keep electrical components dry and test the alternator output routinely. These tractors use a 22-amp generator, sensitive to corrosion.

- Replace the clutch throw-out bearing periodically, especially under heavy loader use.

- Lubricate steering and front axle pivot points to prevent excessive play — a known fatigue spot.

Common Issues & Solutions

Even with its strong design, certain recurring issues do surface among aging Ford 5000 units. Understanding the causes helps prevent downtime in the field.

| Issue | Typical Cause | Solution |

|---|---|---|

| Weak Power Steering on Early Models | A worn hydraulic pump or slack in the steering box | Replace the pump and rebuild the steering column assembly |

| PTO Fails to Engage | Internal clutch wear or linkage misalignment | Inspect control linkage, adjust or replace clutch plates |

| Poor Starting | Weak compression or clogged injectors | Replace injectors and test compression rings |

| Hydraulic Slow to Lift | Low fluid or contaminated filter | Check the hydraulic filter and refill with clean fluid |

| Brake Fade | Worn shoes or disc glaze | Replace brake discs and recalibrate |

| Oil Leaks at Rear Main | Aged gasket or worn seal | Check the rear crank seal during clutch service |

Maintenance simplicity was always the 5000’s advantage. Most components — including the oil pump, fuel injectors, and hydraulic lift pistons — can be serviced using standard shop tools, keeping costs realistic even today.

Ford 5000 Replacement Parts Lookup

For operators rebuilding or maintaining their tractors, reliable aftermarket components ensure continued performance. Whether for the engine, braking system, or hydraulics, sourcing durable parts is key to extending life expectancy in off-road conditions.

At Ford 5000 tractor parts, users will find a full catalog covering essential systems:

All parts are built to fit OEM dimensions for accuracy and corrosion resistance, providing confidence during heavy-duty operations.

Hot Ford 5000 Problems and Answers

The Ford 5000 community remains active decades after its release, and many owners experience answering ongoing technical questions. Below, we’ve simplified consistent and verified insights drawn from long-time operators.

1. Did the Ford 5000 have a differential lock?

Yes. Most models, including the 5100 and 5200, were equipped with a differential lock. It greatly improved traction on muddy or sloped ground — a major benefit for off-road hauling or plowing.

2. What styles or configurations were offered?

The standard lineup included the general-purpose 5100, the 5200 row-crop, and some factory-ordered versions such as high-clearance or vineyard models. The row-crop version featured adjustable axles for row spacing flexibility.

3. Is the engine part of the frame?

Yes, in the Ford 5000, the engine serves as a structural component of the chassis. This reduces overall weight and enhances strength, though proper torqueing during overhaul is crucial to prevent alignment wear.

4. What type of 3-point sensing does it use?

It uses draft control through the top link, allowing automatic reaction to soil resistance during plowing. This is part of why the model excels in heavy tillage work.

5. Was front-wheel assist (FWA) available?

Not from the factory. However, third-party conversions were common — Roadless and County modifications added full-time front-wheel drive systems to certain 5000s, mainly for logging or winter operations.

6. Was power steering standard across all models?

Early versions included manual or low-assist power steering, which was improved in later years. Users report that a well-adjusted later system steers as smoothly as much newer tractors, even under heavy bucket loads.

7. How much horsepower did the Ford 5000 actually produce?

While most listings quote around 69 HP, early diesel models produced closer to 55 HP. The later updates pushed consistent output near 70 HP, depending on fuel type and governor setting.

8. Are parts still available today?

Absolutely. The popularity of the model has encouraged a robust aftermarket supply. Ford 5000 tractor parts include everything from brake discs to hydraulic pumps, ensuring continued usability without excessive cost.

Conclusion

The Ford 5000 remains a benchmark for reliability in off-road and agricultural use. Its heavy-duty engine, efficient hydraulics, and adaptable design made it one of the most trusted tractors of its time — and still one of the most repairable. Operators who maintain their units with timely servicing and high-quality replacement parts can expect many more years of robust field or forestry work. Trusted aftermarket providers like FridayParts make that promise practical by offering durable, globally shipped components at affordable prices.