Coolant is important for regulating engine temperature and preventing overheating. If you don’t fix a coolant leak right away, it can cause costly engine damage. Knowing coolant leak repair and what steps you can take to deal with it will help you make informed decisions.

What Is the Cooling System?

To diagnose and fix a leak properly, you first need to understand the system you’re working on. The cooling system in heavy machinery is a big, tough setup built to handle all the intense heat from a powerful diesel engine running under nonstop load. Machine parts can vary, but the core system always has these key components:

Radiator

The radiator is the cooling system’s main heat-releasing part. Hot coolant from the engine flows through its rows of thin tubes to let the heat escape. A big fan keeps blowing air over it to help cool things down. Radiators for heavy and off-road equipment are built tougher, with wider gaps between the fins. This way, they don’t get clogged up easily with dirt, mud, and debris.

Water Pump

Usually run by a belt or directly by the engine’s gears, this pump forces coolant to circulate through the engine block, cylinder head, radiator, and all the other parts.

Thermostat

Think of this like a smart valve. It stays closed when the engine is cold, so the coolant heats up fast to reach the right operating temperature. Once the engine’s warm enough, it opens up and lets coolant flow to the radiator to cool down.

Hoses

These are thick, reinforced rubber or silicone tubes that connect every part—they’re basically the cooling system’s arteries and veins. They have to hold up to high pressure, extreme hot and cold, and constant machine vibration.

Heater Core

This is a small, secondary radiator inside the operator’s cab. Hot coolant runs through it, and a fan blows air over it to heat the cab. It’s a key part of the whole cooling loop.

Oil Coolers

A lot of heavy machines also use coolant to cool engine oil, transmission fluid, and hydraulic fluid, via separate heat exchangers. If one of these coolers leaks, it’ll cause you to lose coolant, too.

Common Signs You Need Coolant Leak Repair

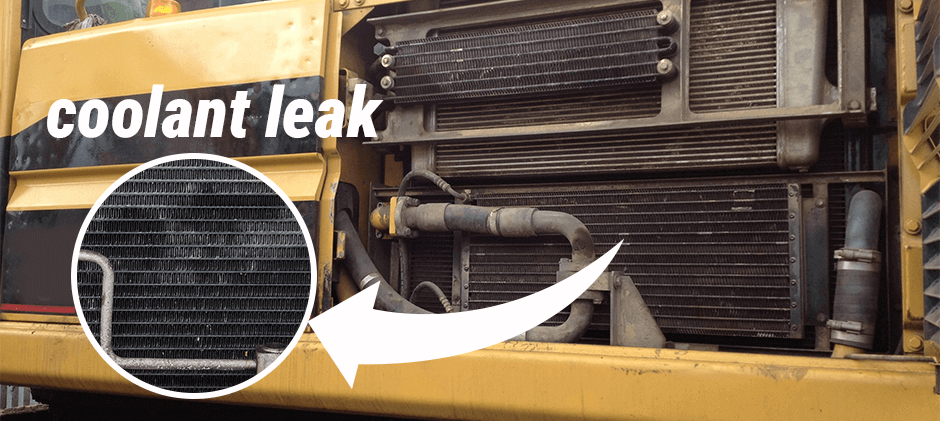

The coolant leaks and definitely leaves marks. If it had been caught earlier, it could have been fixed before it broke the engine. The following are the most common and best-recognized signs of coolant leaks in heavy equipment:

Water Stains Under the Machine

After the machine stopped, there was suddenly a pool of brightly colored, slightly slippery liquid on the ground. Nine times out of ten, the coolant is leaking.

Smell a Sweet Smell

Antifreeze (especially ethylene glycol) has a special sweet taste. After the machine ran for a while, a smell near the engine. Usually, the coolant leaks and is roasted at high temperatures and evaporates.

Coolant Is Not Always Enough

Add it today, and less in two days? This is not “normal consumption”. The cooling system is sealed to begin with, and by constantly adding water, it’s definitely leaking; you just haven’t found the location yet.

Color Marks on Pipes or Parts

Some leak slowly and don’t drip, but when the coolant dries, it leaves white or colored crystals. Focus on: Hose connections, radiator corners, water pumps, and thermostat housings are the most likely to cause problems.

Engine Temperature is too High

The water temperature gauge is higher than usual, or it can rush directly into the red zone, which is a dangerous sign. If the coolant is low, the engine will overheat quickly, and in serious cases, it will directly damage the cylinder head.

White Smoke Is Coming Out

If the exhaust pipe keeps emitting white smoke, it is not simple. It may be that the coolant has run into the combustion chamber, most of which is related to the cylinder pad.

Motor Oil Turns Into “Milkshake”

When I pulled out the oil dipstick, I saw that the oil was white and foamy, like chocolate milk. That’s coolant mixed into the oil. Don’t drive again in this situation and don’t deal with destroying the engine every minute.

How to Repair the Coolant Leak?

Always work on a cool engine. A hot cooling system is under pressure, and it can burn you badly. Put on safety glasses and chemical-resistant gloves before you start.

Find Where the Leak Is Coming From

A tiny drip can get blown around by the fan and look like it’s coming from somewhere totally different.

- Clean the area first: Wipe down the engine and cooling system parts with degreaser and water. A clean engine makes it way easier to spot fresh coolant trails.

- Use a pressure tester: This is the best tool to find leaks. Hook it up to the radiator opening, then pump air into the system by hand until it hits normal operating pressure (usually 15–20 PSI). Once the system’s pressurized, even a super small leak will either drip or hiss—so you can find it right away.

Fix the Leak the Right Way

What you do next depends on which part is leaking.

Leaking Hoses or Clamps

This is a common and the easiest to fix problem. Just tighten the loose clamp. But check the hose, too. If the hose is soft, swollen, or cracked, please replace it. Installing a new clamp on a worn hose is only a temporary way. It is better to cut off the old hose and replace it with a new, high-quality hose.

Radiator Leaks

Leaks from the plastic or metal end tanks, or the seams where the tanks connect to the core, almost always mean you have to take the radiator out for a pro repair—or more often, replace it entirely. A leak in the finned core area (from a puncture) is really hard to fix for good. Don’t use stop-leak products on heavy machinery! They’ll clog up the tiny passages in the radiator, heater core, and oil coolers, and cause way worse overheating problems later. The only reliable fix here is a new radiator.

Water Pump Leaks

Most water pumps have a small “weep hole” on the bottom. A little seepage here is normal, but a steady drip means the internal seal is shot. You can’t repair a leaking water pump—you have to replace it.

Thermostat Housing Leaks

If it’s leaking where the thermostat housing bolts to the engine, the gasket’s probably shot. This fix is super simple: take the housing off, wipe the surfaces clean, then slap in a new gasket and a new thermostat.

Internal Leaks (Like a Blown Head Gasket)

This is a major engine job—it means taking the cylinder head off. White smoke from the exhaust or milky-looking oil is a dead giveaway for this problem. Fixing an internal coolant leak is complicated, so leave it to an experienced heavy equipment mechanic.

Typical Coolant Leak Repairs Cost

Here are some repair costs for the North American market. Prices can swing a lot depending on the machine’s brand, model, and how easy it is to get to the broken part.

| Type of Repair | Estimated Cost (Parts & Labor) |

|---|---|

| Coolant Hose Replacement | $150 – $500 |

| Thermostat & Gasket Replacement | $200 – $600 |

| Water Pump Replacement | $800 – $2,500+ |

| Radiator Replacement | $1,500 – $7,000+ |

| Engine/Hydraulic Oil Cooler | $1,000 – $4,000+ |

| Head Gasket Replacement | $5,000 – $15,000+ |

In Conclusion

Check your cooling system regularly, repair coolant leak, and fix small problems right away—this’ll save you from big, costly repairs down the line. Need a new water pump or other cooling parts? FridayParts is your go-to choice. We stock top-quality, guaranteed compatible parts. Just a few clicks to order, and our secure checkout will give you the safe, reliable online shopping experience you deserve.