If you’ve just discovered that your cylinder head gasket is faulty, you’ll want to know head gasket replacement cost. The answer to is between $5,000–$15,000+. As always, many factors influence price, which we’ll break down in detail here.

What is a Head Gasket?

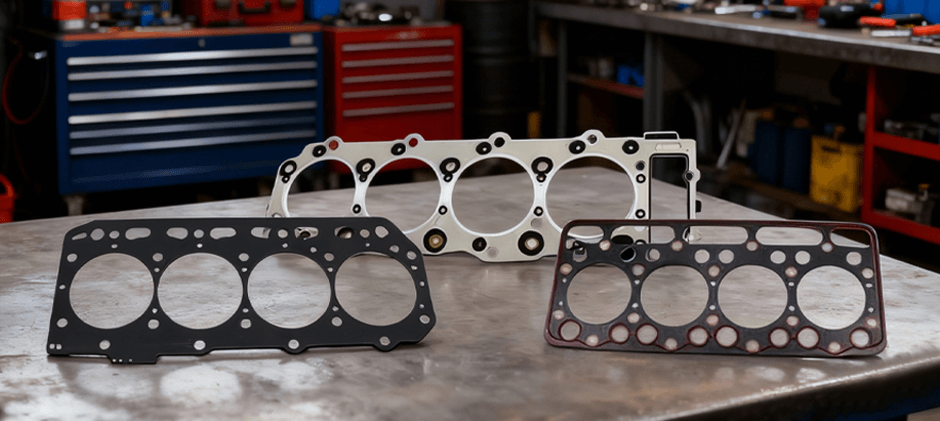

Think of the head gasket as the most important “sealing line of defense” in a heavy equipment engine. It is a precision-designed, multi-layered steel gasket sandwiched between the engine block (where the pistons move up and down) and the cylinder head (where the valves, fuel injectors, camshafts, and other components are installed). It looks simple, but the work intensity is extremely high.

In high-compression diesel engines, the head gasket must simultaneously cope with extreme temperatures and pressures, completing three key tasks:

- Sealing high-pressure gases produced by combustion.

- Keep coolant flowing in the channel to prevent overheating.

- Prevent oil leakage and ensure the upper parts are lubricated.

Once the seal fails, trouble arises—coolant may mix into the oil, combustion gases may enter the cooling system, or oil may seep to the outside. That’s what it’s often said, “blown head basket”, and if it’s not dealt with quickly, it can easily cause serious engine damage.

Head Gasket Replacement Cost Factors

Unlike the simple maintenance of replacing the filter element, replacing the head gasket is not a fixed price. Exactly how much it will cost will vary greatly depending on some key factors of heavy equipment. If you want to roughly judge the repair quote, understanding these influencing factors is the first step.

Equipment Type and Engine Size

Replacing the head gasket on the four-cylinder engine of a small skid steer is completely different from replacing the head gasket on the twelve-cylinder engine of a large mining dump truck. The larger the engine, the more expensive the parts. More cylinders to deal with, and more labor costs when disassembling and installing them.

Labor Rates and Location

The repair location is also critical. Repair in a well-equipped maintenance workshop with low labor costs. Go to a remote construction site for on-site service and the price goes up. On-site replacement costs are often higher. Generally, technicians with licensed heavy-duty diesel charges between $125 and $250 per hour, depending on the region and skill level.

The Severity of the Damage

Did you notice the leak early? Or when the machine overheated, you find it? If the engine overheats, it is easy to deform the cylinder head. The cylinder head must be sent for processing or replacement. This could add thousands of dollars to the repair costs.

Replace Other Parts

In order to repair completely, it is necessary to replace or repair other parts.

- Cylinder Head Bolts: Most diesel engines today use Torque-to-Yield (TTY) bolts. These bolts are stretched when tightened to ensure accurate clamping force. They are disposable and need to be replaced after one use.

- Machining Services: The cylinder head is generally sent to the machining workshop for cleaning, pressure testing (checking for cracks) and flatness testing. Sanding the cylinder head surface is a routine step.

- Additional Gaskets and Fluids: In addition to the head gasket itself, it is common to replace the intake and exhaust manifold pads, valve chamber cover pads, thermostat, and new oil and coolant.

Head Gasket Replacement Cost Estimate

So, what’s the bottom line? While a precise quote requires a full inspection, we can provide realistic cost ranges based on equipment size. These estimates include labor, a standard aftermarket head gasket, cylinder head bolts, fluids, and necessary machine shop services for resurfacing the cylinder head.

- Small Equipment: $3,500 to $8,000. It often takes about 20 to 30 man-hours. Like a skid steer loader, a mini excavator, a compact loader

- Medium Equipment: $9,000 to $18,000. It may take 40 to 60 hours of labor. The price of parts is higher, like standard excavators, wheel loaders, and bulldozers.

- Large Equipment: For large machines, especially those with V-type engines (which have two cylinder heads), costs can start at $20,000 or even exceed $40,000, like large bulldozers, graders, and dump trucks.

Signs of a Leaking Head Gasket

There are some common symptoms of a machine head gasket leak. If these conditions are found, replace them as soon as possible.

- Engine Overheating: If the machine temperature gauge points to the red area, stop operation right now. This is because combustion gases leak into the cooling system, causing overheating.

- White Smoke from the Exhaust: A common sign of coolant burning is white smoke. It smells sweet, unlike the thin steam produced in cold weather.

- Milky Engine Oil: If you check the dipstick or look under the oil fill cap and see a creamy, coffee-colored sludge, it means coolant has contaminated your engine oil. This is catastrophic for bearings and internal components.

- Loss of Power or Rough Running: A breach between two cylinders will cause a loss of compression, leading to a noticeable drop in power and a rough-running engine.

- Bubbles in the Radiator or Coolant Reservoir: With the engine running, visible bubbles in the coolant are a tell-tale sign that combustion gases are being forced into the cooling system.

- External Coolant or Oil Leaks: Sometimes, you can see oil or coolant seeping from the seam. This seam is where the cylinder head connects to the engine block.

Tips for Avoiding Head Gasket Issues

Prevention saves money than repair. Please pay attention to these practices daily. You can greatly extend the head gasket and engine service life.

- Maintain the Cooling System: Keep the radiator clean, and avoid dust and debris in it. And keep enough coolant, using the type and ratio recommended by the manufacturer. By the way, check the water pipes for cracks or aging.

- Follow Proper Operating Procedures: Don’t let the engine suddenly change heat and cold. Wait until the engine heats up to normal temperature, then run at high load. Likewise, before shutting down, just let the engine idle at low speed for a few minutes, and slowly cool down.

- Perform Daily Fluid Checks: A quick check of the oil and coolant levels, spot a problem before it becomes serious.

- Address Issues Promptly: Don’t ignore warning lights and small leaks. Small leaks of coolant can directly cause the engine to overheat if not repaired. The cylinder head gasket may also be damaged.

How is a Head Gasket Replaced? Can I Do It Myself?

Replacing cylinder head gaskets on heavy equipment is never easy or DIY. The engine needs to be partially disassembled and, in some cases, the entire engine even lifted out of the machine for easy operation. The mating surfaces must be flat machined by a professional, a process known in the industry as “block flat machining”. Afterwards, new gaskets were installed and the engine was fully reassembled. Some large diesel engines may have two head gaskets, similar to the left and right head gaskets in some car engines. It is best to have a professional replace it. FridayParts can offer the necessary parts, including cylinder head gaskets, to ensure the repair is completed correctly.

Wrapping Up

Head gasket replacement cost is not cheap, so it is best to have a professional technician do it. FridayParts offers the required parts at a lower price, including cylinder head gaskets. You should also pay attention to maintaining the engine during normal times, which can greatly reduce the failure of the head gasket.