Replacing the engine of a machine is no small expense. In addition to the price of the engine itself, the brand, model and maintenance labor costs must also be included. Different equipment is different, so the final engine replacement cost also fluctuates a lot. Here’s a look at what factors impact replacement costs and some practical budgeting tips to make your decision easier.

Signs of a Failing Engine

Before you decide to replace the engine, confirm it’s truly worn out. Sometimes performance issues come from simple problems. These include a clogged filter or a faulty sensor. First, have a qualified heavy equipment mechanic do a thorough diagnostic. But if you’re seeing these critical symptoms, engine replacement is probably needed soon:

Constant Overheating

If your temperature gauge often goes into the red zone during normal use, that’s a big warning sign. This could mean a cracked engine block or a blown head gasket. Coolant may leak internally because of this. It won’t cool the engine properly. You might also see steam or smoke from the engine bay.

Excessive Oil Consumption or Low Pressure

Does your machine use a lot of oil between changes? And there are no visible leaks? This usually means worn piston rings or valve seals. These let oil get into the combustion chamber. A low oil pressure warning light that won’t go away is more serious. It suggests a failing oil pump or worn internal bearings. This can cause catastrophic failure.

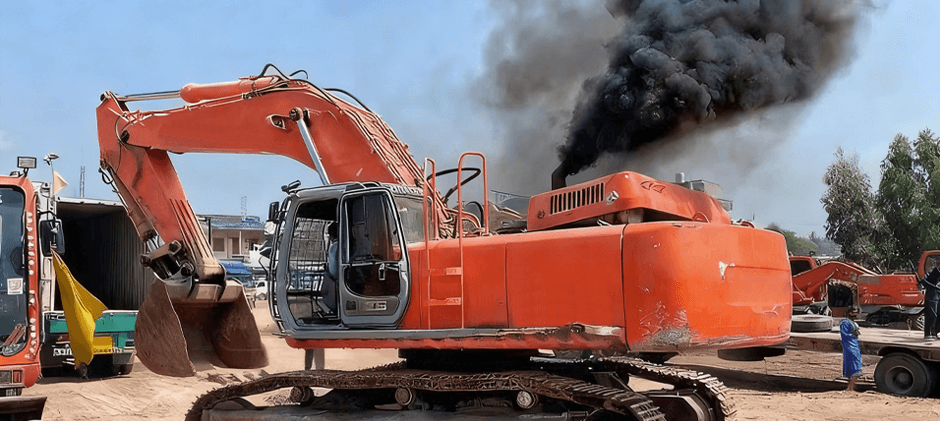

Heavy Exhaust Smoke

Exhaust color helps you diagnose problems. For diesel engines (common in off-road machinery), watch for these:

- Blue Smoke: It means the engine is burning oil.

- Black Smoke: It shows the engine is burning too much fuel. This is often from faulty injectors or a turbocharger problem.

- Thick White Smoke: This is a clear sign. Coolant is getting into the combustion chamber. It’s likely from a cracked head or block.

Strange and Loud Engine Noises

You know how your machine should sound. Any new, ongoing noise is a worry.

- Knocking/Rod Knock: It’s a deep, loud knock. Gets worse when the engine is under load. It often means worn connecting rod bearings. Engine failure will happen soon.

- Tapping or Clicking: A lighter, faster tapping noise may signal a valvetrain problem. This could involve lifters or camshafts. Low oil pressure is often the cause.

- Grinding: Any metal-on-metal grinding noise means severe internal damage. Shut the engine down right away.

Significant Loss of Power

Can your excavator no longer lift what it used to? Is your dozer struggling on slopes? If yes, you have a critical power loss. This could be from internal wear (causing loss of compression). It may also come from a failing turbo or a badly damaged fuel system.

Metal Shavings in Oil

When you change the oil, check the used oil and filter. Look for metallic particles. Fine glitter or larger shavings are clear proof. Internal metal parts are grinding against each other. These parts are failing.

Factors Influencing Engine Replacement Cost

The final invoice for engine replacement isn’t just one number. Several major variables make up the total. Off-road machinery is bigger and more complex than cars. These factors carry even more weight because of that difference. This section holds the key to knowing your total cost.

Engine Brand, Model, and Emissions Tier

Engine brand is the primary cost driver, whether it’s Caterpillar, Cummins, Perkins, Yanmar, or Kubota. Parts for premium, high-horsepower engines naturally come with a higher price tag. The emissions rating also plays a huge role in the total cost. Modern Tier 4 Final engines are far more complex than older Tier 2 or Tier 3 models. They include expensive components: Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) systems, and Diesel Exhaust Fluid (DEF) injectors. Replacing a Tier 4 engine, along with its associated emissions hardware, costs significantly more.

Engine Condition: New, Remanufactured, or Used

You have multiple options to choose from — each comes with a different price and reliability level.

- New: A new crate engine comes directly from the manufacturer, brand-new and unused. It’s the priciest option on the list. But it has zero operating hours and the best factory warranty available.

- Remanufactured: Remanufactured engines strike the best balance of cost and reliability, making them the most popular choice. Technicians completely disassemble, clean, and inspect every part of the engine. All worn or out-of-spec components get replaced with new ones. The engine is then reassembled and tested to meet or even exceed the original factory standards. Most reman engines come with a solid, trustworthy warranty.

- Rebuilt: A rebuilt engine only has its failed parts replaced — no full teardown or comprehensive inspection. Quality varies a lot depending on the rebuilder’s skill and attention to detail. It costs less than a reman engine. But it carries more risk of future issues and usually comes with a more limited warranty.

- Used: A used salvage engine is a functional unit pulled from a salvaged machine. It’s the cheapest option by far. But it’s also the riskiest choice. You won’t know its full history, how well it was maintained, or its true operating hours. Little to no warranty typically comes with a used salvage engine.

Scope of the Replacement (Long Block vs. Complete Drop-In)

Inclusion of parts directly impacts the total replacement cost. A “long block” usually includes the engine block, cylinder head, and all internal rotating components. You’ll reuse your current fuel system, turbo, manifolds, and accessories with this option. A complete “drop-in” engine comes fully equipped with all necessary accessories. This full setup allows for faster installation. But it also comes with a higher initial cost compared to a long block.

Associated Parts

Engine failure often leads to collateral damage. Debris might contaminate the turbocharger, or the radiator could get clogged. Replacing certain wear items during the engine swap is also a smart move.

What Is a Fair Labor Cost for an Engine Replacement?

Labor makes up a huge portion of the total engine replacement cost. Heavy equipment engines are large, heavy, and tightly integrated with the machine’s hydraulic and electrical systems. This kind of work never happens quickly.

- Labor Hours: The time required varies by machine. A compact tractor engine might take 15-30 hours, while a mid-size excavator could easily take 40-60 hours or more, especially if there are complications.

- Hourly Rates: Expect to pay $125 to $225 per hour for a qualified heavy equipment technician. Dealerships are typically at the higher end of this range, while reputable independent shops may be more moderate.

- Field Service vs. Shop Service: If your machine is immobile, you’ll need a mobile mechanic. They charge a premium for travel time and on-site work, but it saves you the massive cost of transporting a disabled machine.

A fair labor cost comes down to one simple calculation: the shop’s trusted hourly rate multiplied by the standard book hours for the job. Take a 40-hour job as an example — at $175 per hour, labor alone adds up to $7,000.

Tips for Budgeting Engine Replacement Cost

Facing a five-figure repair bill is never easy, but you can take practical steps to manage it.

Set Aside a Contingency Fund

Always add 15-20% to your initial quote for unexpected costs. During teardown, mechanics might discover hidden issues, a cracked manifold, a worn hydraulic pump coupler, or other surprises. This buffer keeps you from going over budget.

Get Multiple Quotes

Don’t settle for the first price you receive. Gather quotes for the engine itself from dealers and remanufacturers. Also, get labor quotes from different repair shops. Compare warranties just as carefully as you compare prices.

Use High-Quality Aftermarket Parts for Accessories

Engine core components demand top quality, but you can cut costs wisely with aftermarket parts for accessories. For items like sensors, belts, filters, and water pumps, reputable aftermarket suppliers offer high-quality, fully compatible options. These parts cost a fraction of OEM prices. A smart way to lower the total bill without sacrificing reliability.

Review Warranty Coverage

New or remanufactured engines come with a parts warranty, usually 1-2 years. Your repair shop should also stand behind its labor with a warranty. Make sure you understand exactly what’s covered and how long the coverage lasts.

Can I Replace My Engine Myself to Save on Labor Costs?

Technically, you could do it yourself. Realistically, most owners shouldn’t. The risk of personal injury runs extremely high with this job. You might also damage the new engine or make critical mistakes that void the warranty. For a task of this scale, professional labor costs act as an investment. They ensure the job gets done correctly.

Final Thoughts

Calculating engine replacement costs is complex, as many factors affect it. These factors range from the type of engine you choose to related labor costs. When you have a mechanic do the job, the total cost can be $10,000 or more. Choose reliable aftermarket engine parts to cut costs. Make FridayParts your one-stop shop for aftermarket engine parts. We guarantee compatibility with your engine’s brand and model.