Hydraulic systems are the powerhouse of every heavy machine — from loaders and excavators to compact tractors. They lift, dig, steer, and drive by transferring force through a vital medium: hydraulic fluid. When this fluid drops below the proper level or becomes contaminated, the entire system suffers. In this article, we’ll explain why hydraulic maintenance is crucial, how to check the hydraulic fluid on your John Deere tractor (including a detailed example from the popular John Deere 2032R model), and smart tips for keeping your system in top shape. Whether you operate in the field, forest, or construction site, this guide helps you minimize downtime and extend your machine’s working life.

Why Hydraulic Maintenance Matters?

Hydraulic pressure is what allows your tractor to lift a load effortlessly. The system’s hydraulic fluid transfers power from the pump to the cylinders, steering units, and transmission. But beyond energy transfer, this fluid performs several other key roles:

- Lubrication: reduces friction between metal parts.

- Cooling: carries heat away from pumps and valves.

- Contamination control: gathers debris so filters can trap it.

- Corrosion prevention: forms a protective film on components.

Running a machine with low or dirty hydraulic fluid can cause:

- Jerky or unresponsive controls.

- Cavitation noise in pumps.

- Overheating and power loss.

- Premature seal and gear wear.

That’s why technicians recommend checking hydraulic fluid levels every 50 operating hours or weekly during heavy workloads.

How to Check John Deere Hydraulic Fluid?

The process is simple but must be done precisely for accurate readings. Let’s walk through it step‑by‑step — focusing on the John Deere 2032R model, which many operators use as their compact workhorse.

1. Park the Tractor and Prepare Safely

Before doing anything, ensure your equipment is on level ground. Lower all attachments and implements to release hydraulic pressure. Set the parking brake and turn off the engine.

Key: Tractor should be on level ground with hitch in the lowered position and engine stopped when checking oil level.

This position prevents residual oil from remaining in the lift or steering cylinders, which could give a false low reading.

2. Warm Up the System

Start the engine and run it at approximately 1000 RPM for one minute. This circulates the hydraulic oil through the system. Then, stop the engine and wait about three minutes for the oil to settle back into the reservoir.

For consistency, always check when the oil temperature is about 45 °C (113 °F) — oil expands when hot, so cold readings can appear slightly low.

3. Locate the Sight Glass or Dipstick

Depending on your tractor model, you’ll have either a sight glass or a dipstick:

| Model Type | Inspection Method | Location Details |

|---|---|---|

| Compact (e.g., 3032E, 3038E) | Sight glass window | Rear axle housing near PTO shaft |

| 2032R Gen 1 | Dipstick | Left side under the seat, near the PTO selector lever |

| Large utility tractors | Dual check points | Both the rear sight glass & the transmission dipstick |

Many 2032R owners report that the dipstick is easy to miss, hidden low between the frame rails near the fender. The handle loop is small and black, blending with the housing. Using a flashlight helps. Hook the loop with a wire or tool and pull firmly — it may lodge tightly due to the rubber seal.

4. Read the Hydraulic Fluid Level

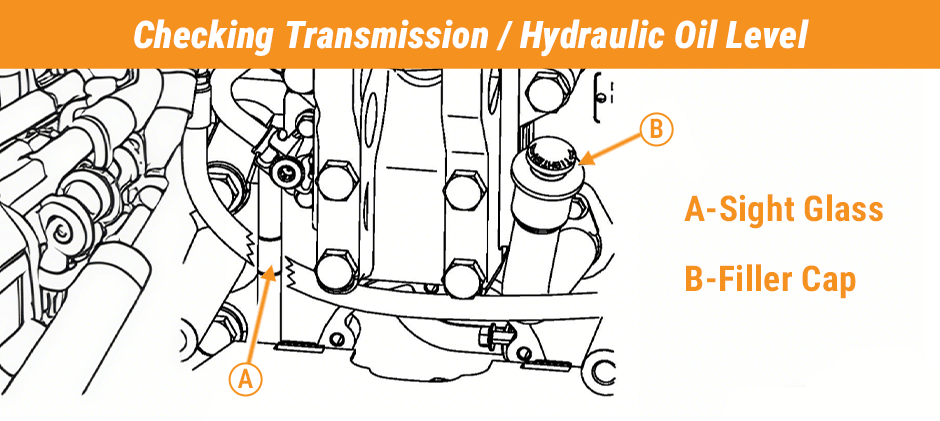

- Sight Glass Models: Look for the circle marked “A” on the rear case (see image reference). The fluid line should be between the two marks, ideally near the upper one.

- Dipstick Models: Clean the dipstick, reinsert fully, then remove again to read. The film of oil should reach the top mark.

| Reading | Meaning | Recommended Action |

|---|---|---|

| Below the lower mark | Fluid too low | Add hydraulic fluid |

| Between marks | Normal range | No action needed |

| Above the top mark | Overfilled | Drain excess oil |

A level beyond the top mark traps pressure inside and may cause heat buildup or power loss during transport.

5. Add Hydraulic Fluid (If Required)

If the level is low, follow this safe‑fill method:

- Wipe around the filler cap (B) to keep dust out.

- Remove the cap and insert a clean funnel.

- Slowly add John Deere Hy‑Gard or equivalent hydraulic fluid until it reaches the mark.

- Replace the filler cap securely.

IMPORTANT: Change fluid immediately if you notice milky or cloudy oil — this means water contamination.

After filling, run the engine briefly, then re‑check to confirm the correct level.

6. The Hidden Lesson from the 2032R Forum Owners

On several farming forums, experienced 2032R users emphasize that visual checks alone can be misleading. The fluid is often clear and nearly invisible unless dyed red. One operator mentioned never seeing anything in the sight glass until adding colored fluid for contrast.

Real‑world insight:

Always rely on the dipstick or marks rather than assuming “full” by visual appearance. Lighting or temperature can distort how full the glass looks.

This example underscores why every maintenance schedule should include both routine inspection and component awareness — especially for smaller tractors with compact hydraulic housings.

Tips for Checking Hydraulic Fluid

Maintaining your hydraulic fluid properly doesn’t stop with measuring levels. Here are practical guidelines that professionals follow to keep off‑road machinery reliable:

1. Keep everything spotless.

Even tiny dirt particles can destroy precision valves. Always clean filler caps, funnels, and area surfaces before opening any port.

2. Inspect regularly for leaks.

A small oil stain beneath your John Deere could mean a failing seal or cracked line. Track leaks early before pressure drops affect steering or lift performance.

3. Monitor fluid condition.

Good hydraulic oil is translucent and amber‑clear. Replace immediately if it looks dark, milky, or smells burnt.

4. Turn maintenance into routine.

Change the oil and filters every 1,200 hours or annually. Contaminated or aged oil stresses pumps and can lead to cavitation.

5. Use the right replacement parts.

When replacing hydraulic filters, pumps, or seals, using reliable aftermarket components ensures system compatibility and cost‑effective repairs. Trusted suppliers like John Deere tractor parts offer a wide inventory of hydraulic quick‑connect couplers, solenoid valves, and water pumps suited for your specific model.

Common Mistakes to Avoid

- Checking levels on uneven ground or with implements raised.

- Mixing different types or brands of hydraulic fluid.

- Forgetting to warm the system before checking.

- Overfilling — causing foaming and heat issues.

When to Replace Hydraulic Fluid?

Beyond checking levels, make sure the hydraulic fluid itself isn’t worn out.

Replace it:

- After 1,200–1,500 hours of use.

- Whenever you replace major hydraulic components.

- If contaminated by water, coolant, or dirt.

Flushing the system is a better choice during major repairs — it removes old oil from lines, pumps, and valve blocks.

Recommended Fluids and Parts

John Deere machines often require transmission + hydraulic shared reservoirs. Use low‑viscosity Hy‑Gard oil for colder climates or regular Hy‑Gard for general agricultural and construction use. Equivalent aftermarket options also exist that meet JDM J20C or J20D specifications.

If your hydraulic components show wear — like failing couplers, leaking pumps, or noisy valves — consider replacing them with dependable aftermarket units such as the hydraulic quick‑connect coupler kit AT312877 or the hydraulic pump assemblies available at John Deere parts. FridayParts supplies quality replacements at competitive prices for tractors, loaders, and excavators alike.

Conclusion

A few extra minutes maintaining your hydraulic fluid level pays off in thousands saved on repairs. By keeping your off‑road machine well‑lubricated, leak‑free, and properly filled, you ensure steady performance through every season. When it’s time to replace worn parts or replenish your hydraulic system, explore top‑quality aftermarket John Deere parts at FridayParts.com — the convenient source for pumps, filters, bearings, injectors, and couplers built for durability and value.