When your off-road machinery—such as a skid steer, scissor lift, tractor, or generator—stops starting on-site, the problem often traces back to one simple issue: a faulty battery connection. Many operators still struggle with recognizing the positive and negative terminals correctly, especially when terminals are rusted, covered, or faded. In this guide, we’ll explain how to distinguish battery polarity safely and precisely, how color codes and size cues help, and how to avoid expensive electrical failures in field conditions.

How to Tell a Tractor Battery Positive and Negative?

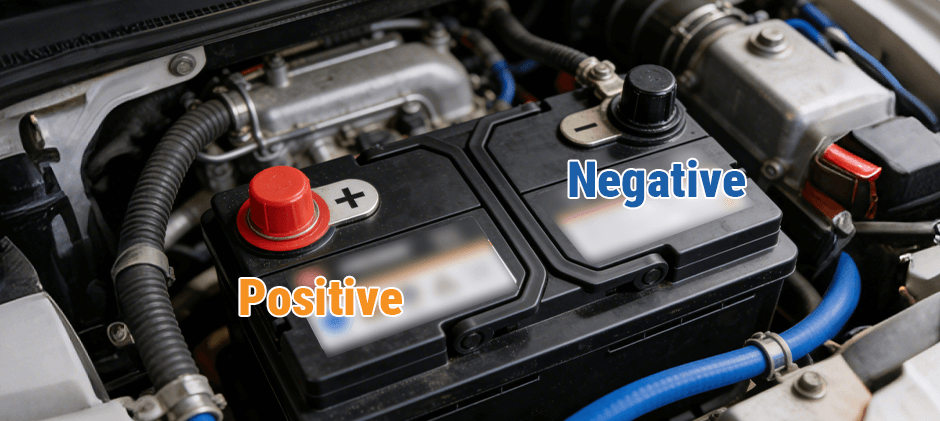

For most off-road equipment, including tractors, generators, and telehandlers, the identification principles are consistent.

Here’s what you should look for step by step:

1. Check the Markings:

Most heavy-duty or agricultural batteries have the symbols “+” (positive) and “–” (negative) stamped near the posts. These are the most reliable visual cues, even when cables are color-faded.

2. Follow the Color Code:

- The red cable or post represents the positive terminal.

- The black cable or post stands for the negative terminal.

Red cables usually lead to solenoids, starters, or charging controllers; black ones connect directly to chassis ground.

3. Compare Terminal Sizes:

The positive post is slightly larger than the negative. This design prevents misconnection of the clamps or lugs when replacing or charging the battery in the field.

4. Use a Multimeter:

Set the multimeter to DC voltage. Connect the red probe to one post and the black to another:

- A positive reading (e.g., +24.5V) means the red probe is on the positive terminal.

- A negative reading (e.g., –24.5V) means the red probe is touching the negative side.

Pro Tip: In older off-road equipment, faded paint or rewired terminals can mislead you—always confirm polarity with a multimeter before jump-starting.

What Color is Negative on a Battery?

The universal standard for off-road and industrial batteries is black for negative and red for positive. However, harsh environments can make color unreliable:

- Mud, oil, or UV exposure may cause color fading.

- Aftermarket wiring replacements in field repairs may not follow original color schemes.

- Battery caps and connectors are sometimes standardized differently across manufacturers.

If color coding is unclear:

- Look for stamped polarity symbols on the plastic casing.

- Inspect cable routing — grounding wires (connected to the chassis frame) almost always lead from the negative side.

- Check existing service diagrams, especially for multi-battery 24V or 48V systems, which are common in large aerial platforms and electric lifts.

Things You Should Know

Correct polarity isn’t just about knowing “red from black.” It’s about maintaining the electrical safety and longevity of your off-road battery systems.

Safety Essentials

- Always disconnect the negative terminal first when removing a battery and reconnect it last when installing.

- Use non-conductive tools to prevent shorting.

- Avoid leaning over open batteries during charging—gas buildup can ignite.

- Never connect a charger until the terminals are correctly identified and secured.

Charging Efficiency Tips

Use a compatible voltage-rated charger. For example:

- 12V for generators and small tractors.

- 24V for scissor lifts, skid steers, and floor scrubbers.

- 48V for larger boom lifts or electric forklifts.

Always cross-verify your machine’s specifications before connecting a heavy-duty charger.

For safe and efficient battery charge operations, consider using robust and weatherproof equipment. Explore trusted solutions here: battery charge.

Common Mistakes to Avoid

1. Assuming All Red Wires Are Positive:

Field rewiring or OEM modifications may lead to mismatched cable colors. Never rely solely on paint or tape indicators.

2. Skipping Ground Verification:

Always confirm which cable connects to the metal body—this is your reliable ground reference.

3. Mixing Battery Banks in Series/Parallel Without Labels:

In 24V lift systems, connecting two 12V batteries backward can instantly short-circuit chargers or controllers.

4. Neglecting Maintenance:

Corrosion and dirt buildup obscure markings—clean terminals routinely to prolong battery life.

Conclusion

Identifying battery polarity correctly isn’t a trivial skill—it’s essential maintenance knowledge for any off-road machinery operator. From tractors to aerial lifts, correct polarity ensures safe operation, efficient charging, and longer component life.

At FridayParts, you’ll find an extensive inventory of affordable aftermarket components, including battery chargers built for rugged conditions. With our competitive pricing, fast delivery, and quality-tested compatibility, your equipment runs smoother and safer—every shift, on every site.