When one heavy-duty machine comes to shows hesitation, gives out black smoke from the exhaust, or cannot maintain strong pulling power when under heavy load, the main cause many times is often not from injectors, and not even from the fuel pump itself, but from a fuel pressure regulator that is starting to fail. For those owners and technicians who are dealing with off-road and construction machines, testing this part in the correct way can help avoid long downtime, wrong judgment of the problem, and unnecessary cost for part changes. This guide will explain how the regulator works, give practical steps for testing, provide safety advice, and tell when the replacement should be considered.

The Function of the Fuel Pressure Regulator

The fuel pressure regulator (FPR) maintains the fuel rail pressure at a fixed and balanced level, ensuring the injectors deliver a consistent fuel flow. In heavy equipment diesel systems—such as those on loaders, dozers, or excavators—the regulator controls the return flow back to the tank or manages pressure inside the common‑rail circuit.

Here’s what it does:

- Balances system pressure so injection timing remains accurate under changing load and RPM.

- Prevents overpressure that could damage injector seals or over‑fuel the engine.

- Avoids low‑pressure conditions, which cause lean combustion and possible injector misfires.

Mechanical regulators rely on springs and diaphragms, while modern Tier‑4 compliant engines use electronic control valves. Whether mechanical or electronic, the principle never changes—stable fuel pressure equals stable combustion.

How to Test a Fuel Pressure Regulator?

Diagnosing a failed regulator is a hands‑on process. Before assuming your pump or injectors are faulty, we should isolate the FPR and test its operation.

1. Prepare for a Pressure Test

You’ll need:

- A fuel pressure gauge or injection testing kit

- Vacuum line caps and locking pliers (for mechanical styles)

- A fuel system diagram for your specific machine

- Safety gear—gloves, glasses, and absorbent rags

Follow these steps carefully in a well‑ventilated area. Disconnect the battery if the system uses high‑pressure lines.

2. Establish Baseline Pressure

1. Locate the test port — most heavy‑equipped diesel rails have a service port or sensor port.

2. Attach the gauge, ensuring a tight seal.

3. Start the engine and monitor the reading at idle.

- Compare to the manufacturer’s specification. A typical diesel common‑rail system will read several thousand psi; a gasoline engine regulator will show 35–45 psi.

4. Observe pressure changes when you rev the engine or apply the hydraulic load.

If the pressure drops significantly under acceleration, you might suspect the pump. But if the pressure climbs too high or fluctuates erratically, the regulator is the likely issue.

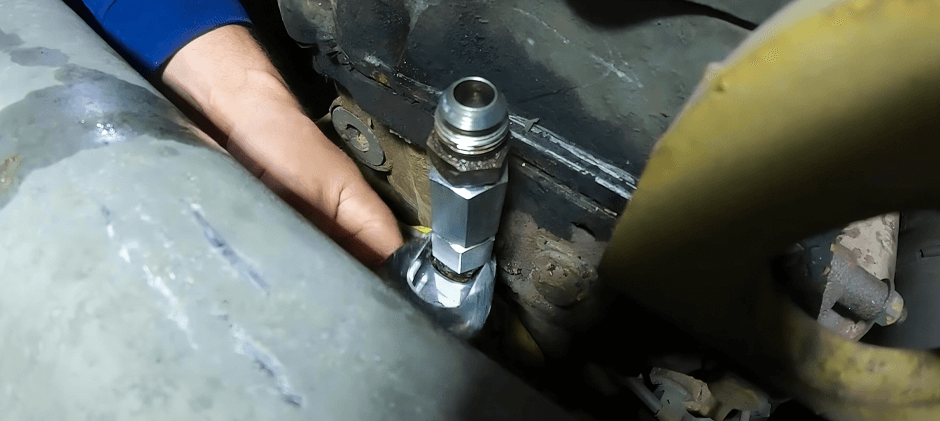

3. Quick Tip: The “Return‑Line Pinch” Test

A simple field method adapted from technician forums works for both light and heavy machinery:

- While the engine runs, use locking needle‑nose pliers with rubber caps to pinch the return line gently.

- If the pressure climbs immediately, the regulator is bleeding off too early—replace or adjust it.

- If no change occurs, the fuel pump cannot generate enough pressure, meaning the pump or its filter stage is at fault.

Another option: reroute the return fuel line to a container. If you see fuel steadily flowing, the regulator is opening too soon; if there’s no flow, the pump may be weak.

4. Check Diaphragm Health

For vacuum‑operated regulators (common in equipment with smaller gasoline engines or auxiliary power units):

- Disconnect the vacuum hose.

- Inspect for fuel traces inside the hose—a clear sign of a ruptured diaphragm.

- Reconnect and remove the vacuum manually; a healthy regulator’s pressure will rise 5–10 psi. No pressure change means internal failure.

5. Key‑On/Engine‑Off Test

Cycle the ignition so the pump primes, but the engine does not start. The pressure should rise instantly and hold steady. If the needle on the gauge falls within seconds, the regulator’s internal valve is leaking, or the sealing seat is worn.

| Observation | Possible Fault |

|---|---|

| Pressure spikes too high | Stuck regulator or blocked return |

| Pressure slowly bleeds off | Leaking diaphragm or seat |

| Pressure is too low even at the prime | Weak pump or clogged filter |

6. Testing Electronically Controlled Regulators

In newer off‑road machines, fuel pressure regulation happens via a solenoid valve. Use a multimeter or scan tool to verify the duty cycle and feedback signals:

- Command signal from ECU should vary between 20–80 % duty as load increases.

- If the solenoid doesn’t respond electrically but the pump and wiring check out, the regulator must be replaced.

At this stage, consider sourcing a replacement from a trusted aftermarket supplier that specializes in heavy equipment—such as hydraulic parts and fuel system components designed for compatibility with major OEMs.

7. Common Misinterpretations: Pump vs. Regulator

Field technicians often misdiagnose low‑pressure issues as a bad pump. But the quick‑return test often reveals the opposite. If the regulator is weak, it opens too early and sends precious fuel back to the tank instead of the injectors. Testing both together narrows down the issue precisely.

For additional insight on early‑stage failures—such as black smoke, poor idle, or excessive fuel return—refer to our guide on signs of fuel pressure regulator malfunction, inspired by this detailed reference.

Safety Tips for Testing

Working with pressurized diesel is hazardous. Always follow these safety principles:

- Depressurize the system before disconnecting any lines. Relieve pressure via the service port or disconnect the fuel pump relay.

- Avoid sparks and open flames. Diesel vapor is less volatile than gasoline but still flammable.

- Wear gloves and goggles. Heated fuel can cause skin irritation.

- Ensure you work on stable, level ground, especially with heavy machinery that may shift when powered.

- Keep a fire extinguisher nearby during any live test.

Main Cause of FPR Failure

Knowing why a regulator fails helps prevent future breakdowns.

- Contaminated fuel: Dirt or micro‑debris from storage tanks wears out valve seats.

- Corrosion: Moisture in diesel lines can rust internal springs.

- Overpressure from clogged filters: A blocked return or primary filter stresses the regulator.

- Heat and vibration: Heavy machinery operates in harsh environments, which can crack diaphragm housings.

- Improper installation: Over‑tightening, missing O‑rings, or incompatible aftermarket fittings lead to premature leaks.

Routine inspections during scheduled maintenance—alongside replacing fuel filters—can detect these issues early. Always lubricate O‑rings with clean diesel or PTFE‑safe grease before assembly.

When to Replace the Fuel Pressure Regulator?

You should replace the fuel pressure regulator if any of the following occur:

- Measured pressure fails to match the manufacturer’s spec even after pump verification.

- Fuel leaks into the vacuum line or out from the vent hole.

- The engine exhibits consistent rich or lean conditions.

- Diagnostic scan shows unresponsive or shorted fuel pressure control solenoid.

If the regulator proves faulty, avoid overpaying at a dealership. Heavy‑duty replacement options such as fuel pressure regulator assemblies for Caterpillar, Deutz, and Yanmar engines deliver OEM‑grade performance for far less. At FridayParts, aftermarket parts are tested for durability across a wide range of off‑road machinery, from loaders to power generators.

Practical Takeaways

| Condition | Pressure Behavior | Likely Cause | Recommendation |

|---|---|---|---|

| Low pressure on the gauge | Underload, pressure drops below spec | Weak pump or clogged filter | Inspect fuel lines; then test with the return‑line pinch |

| High, constant pressure | Rise exceeds spec even at idle | Regulator stuck closed | Replace regulator |

| Pressure fluctuates rapidly | Oscillates 5–10 psi under constant rpm | Faulty diaphragm | Replace regulator |

| Slow leakdown post‑shutdown | Pressure decays quickly | Valve seat leak | Replace the regulator or pump check valve |

Routine Maintenance Matters

Routine testing of fuel pressure regulators not only keeps your engine performing efficiently but also reduces long‑term operating costs. A typical inspection every 1,000 hours of heavy equipment use can:

- Improve power response under load

- Reduce unburned fuel emissions

- Prevent premature injector wear

- Extend pump life by avoiding overwork

Combining scheduled fuel system checks with hydraulic system upkeep ensures your machinery stays productive through every job cycle. You can browse high‑quality hydraulic parts to complete your maintenance toolkit.

Keep Your Machine Running Strong!

Testing and maintaining the fuel pressure regulator is one of the simplest but also very powerful methods to keep the off-road machinery in reliable condition. It can save much time for diagnosis, ensure the engine always outputs stable power, and avoid many unnecessary replacement expenses.

If your testing result already proves the regulator has failed, you can believe FridayParts to offer you one affordable and OEM-standard replacement with very fast delivery. With a very wide inventory, good competition price, and fitment for many famous equipment brands, FridayParts will help your machinery return to full working pressure again — in a safe and highly efficient way.