When an off-road machine won’t crank after a shift, keeps killing a battery, or shows dim/flickering work lights, we usually face the same question: is the alternator failing, or is something else in the charging system dragging voltage down? In this guide, we’ll show clear signs of a bad unit, explain the “disconnect the battery” test (and why it’s risky on modern equipment), and give safer, more accurate checks you can do with a meter so you fix the real problem without causing new damage.

How Do You Know the Equipment Alternator is Bad?

On off-road machinery, the alternator is the main power source once the engine is running. It supports loads (ECU, fuel shutoff, sensors, lights, HVAC, joystick controls, safety systems) and recharges the battery after starts and idle periods. When output drops or becomes unstable, symptoms show up fast—especially on machines that idle a lot or run many accessories.

Common signs we see in the field

- Battery/charge warning lamp on the display (if equipped)

- Slow cranking after normal work hours (even with a “new” battery)

- Dim or flickering lights, especially at low RPM

- Intermittent electrical glitches (gauges reset, radio/telematics drop, controller faults)

- Burning rubber smell (belt slip) or electrical smell near the alternator

- Whining/grinding noise from the alternator area (bearing wear)

- Frequent jump-starts that only help temporarily

A quick symptom-to-cause table (saves time)

| What we notice | Likely direction | What we check first |

|---|---|---|

| The battery keeps dying overnight | Parasitic draw / weak battery | Key-off draw, battery condition, cables |

| The battery dies during operation | Charging system issue | Alternator output voltage, belt, wiring |

| Lights brighten too much / bulbs fail | Overcharging | Regulator/field control, sense wire |

| Good voltage at the alternator, low at the battery | Voltage drop | Main charge cable, grounds, connectors |

| The problem happens after rain/washdown | Moisture/corrosion | Plugs, terminals, and harness routing |

Key point: a “bad alternator” complaint is often a wiring, belt, ground, or battery problem. So we want proof before replacing parts.

How to test alternators by disconnecting the battery?

Many people have heard this rule: “If you disconnect the battery while the engine is running and it keeps running, the alternator is good.” That’s a legacy test, and on modern off-road machines, it can be a bad idea.

Why is disconnecting the battery risky on off-road equipment?

The battery is not just a starter box—it also acts like a voltage stabilizer. When you remove it while the alternator is producing power, the system can see a voltage spike. That spike can damage:

- The alternator’s regulator (internal or external)

- ECUs/controllers and display modules

- Relays, sensors, and communication networks

- Sensitive accessories (telematics, cameras, GPS)

Our recommendation: use a multimeter-based test as the primary method. Only consider the disconnect test on older, simple machines with minimal electronics, and only if you accept the risk.

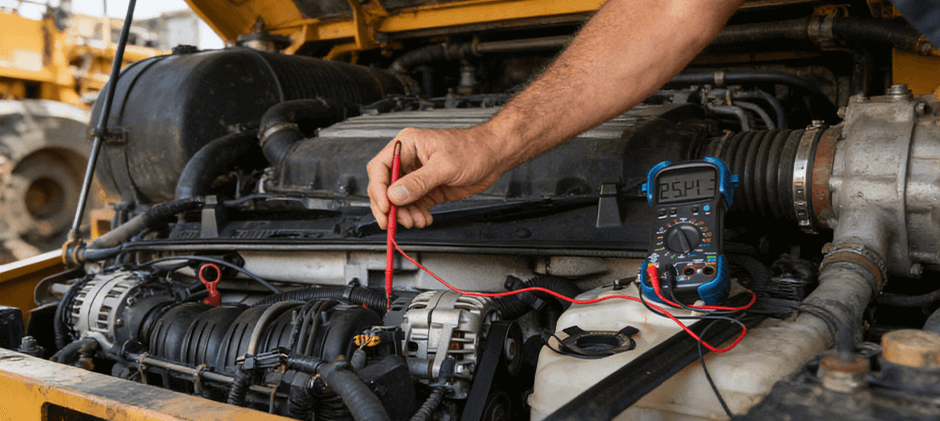

The safer, more reliable way (recommended): multimeter charging test

Even if your outline focuses on disconnecting, this is the method we use first because it protects the machine and gives real numbers.

Step A — Baseline battery voltage (engine OFF)

- Set the multimeter to DC volts (20V range for 12V systems; for 24V systems, use an appropriate higher range).

- Probe at the battery terminals (not on cable clamps if possible).

- Typical baseline readings:

- 12V system: ~12.4–12.6V for a healthy, rested battery

- 24V system: ~24.8–25.2V (varies by battery type and state of charge)

If baseline voltage is already low, an alternator test can mislead us because the battery may be too weak to stabilize the system.

Step B — Charging voltage (engine running, idle)

- Start the engine and let it idle.

- Measure the voltage again at the battery.

- Typical targets:

- 12V system: roughly 13.8–14.6V

- 24V system: roughly 27.6–29.2V

If voltage stays near baseline (around 12.x or 24.x), the alternator likely isn’t charging—or the charge path is broken.

Step C — Loaded charging test (work lights/blower ON)

Turn on major loads (work lights, cab fan, heater, etc.) and watch voltage:

- A healthy system should hold close to regulated voltage (it may dip slightly and recover).

- If the voltage falls hard and keeps dropping, the output is weak, or there’s a large voltage drop in wiring/grounds.

If you still want the “disconnect the battery” test (use caution)

If you choose to do it anyway, we will keep it controlled, and we will only disconnect the negative terminal.

- Park safely, attachments down, area clear.

- Keep RPM at idle (don’t rev).

- Turn off non-essential loads.

- Wearing eye/hand protection, loosen the negative (-) battery terminal.

- Briefly remove the negative cable and observe:

- If the engine immediately stumbles/dies: charging is likely not supporting the system.

- If the engine continues, it suggests the alternator is producing power, but it does not prove the alternator is healthy under load.

Important limitations:

- A weak alternator may still keep the engine running at idle, then fail under load.

- A wiring fault can still exist even if the alternator itself is fine.

- On electronically controlled machines, this test can cause expensive damage.

If testing confirms the alternator is weak, replacement is often the most effective way to prevent repeated downtime. For sourcing a compatible unit for heavy equipment, you can start by matching your model and part number in this alternator category. It’s often more cost-effective than purchasing only OEM parts while still obtaining a part that fits your application.

Troubleshooting Beyond the Alternator

When the charging voltage looks wrong, we don’t stop at “replace alternator.” Off-road machinery lives in vibration, dust, moisture, and heat—perfect conditions for voltage drop and connection failures.

1) Belt and pulley checks (fast, high value)

- Inspect the belt for glazing, cracks, and missing ribs

- Check tensioner operation and alignment

- Look for belt dust around pulleys (slip sign)

A slipping belt can mimic a failing alternator, especially when hydraulic loads increase engine demand.

2) Voltage drop testing (find hidden resistance)

A system can show “good alternator output” but still starve the battery because of resistance.

We measure voltage drop with the engine running and loads on:

- Positive side drop: alternator B+ to battery positive

- Ground side drop: alternator case to battery negative

Big drops point to:

- corroded terminals

- loose lugs

- damaged charge cable

- weak frame/engine grounds

3) Field/sense wiring and connectors

Many alternators rely on small control wires (sense/field/ignition). A broken or corroded control wire can cause:

- no charging

- low charging

- overcharging

We inspect connectors for:

- pushed pins

- green corrosion

- oil intrusion

- harness rub-through near clamps

4) Battery health (a bad battery can “frame” the alternator)

A failing battery can pull voltage down and make a good alternator look bad. Checks we use:

- resting voltage after charge

- load test/conductance test (if available)

- inspection for swelling, leaks, loose posts

If the battery is weak, we fix that first—or we’ll misdiagnose the charging system.

5) Charging support for fleets: using the right charger

Many off-road fleets depend on chargers to recover batteries during downtime (cold weather, long idle, seasonal machines). When choosing a charger, two specs matter most:

- Voltage compatibility (12V / 24V / 36V / 48V)

- Amperage output (higher amps = faster charging, but too high can overheat or shorten battery life)

FridayParts’ charger category highlights these points and lists heavy-duty options across common voltages and amp ranges, with safety features like reverse connection and overcharge protection. If your issue is repeated low state-of-charge (rather than a dead alternator), pairing proper testing with a correct battery charger can reduce jump-starts and extend battery service life.

Conclusion

To confirm an alternator problem on off-road machinery, we rely on measured voltage—engine off, engine running, and under load—because it’s safer and more accurate than disconnecting the battery. The disconnect test can cause voltage spikes and doesn’t prove the alternator can handle real loads. When readings are off, we also check belts, grounds, wiring voltage drop, and battery health so we fix the root cause, not just the symptom.