When you’re behind the controls of an excavator, the joystick becomes your main tool for getting work done. Whether you’re digging trenches, moving dirt, or grading land, knowing how to use these controls the right way can make the difference between a smooth day on the job and a frustrating mess. I’ve put together this guide to walk you through everything you need to know about excavator joystick controls, from the basics to the stuff that’ll help you work like a pro.

What Is an Excavator Joystick?

An excavator joystick is the control stick that lets you manage the machine’s movements. Mini excavators and full-size machines come equipped with two control joysticks that work together to control the boom, bucket, dipper (also called the stick), and swing functions. Think of them as your hands reaching out to do the work – when you move the excavator joystick in a direction, the machine responds by moving that specific part.

These joysticks use hydraulic or electronic systems to send commands to the excavator’s parts. Every push, pull, or side movement you make translates into precise actions from the machine. The beauty of modern joystick systems is that they let you combine movements – you can lift the boom while curling the bucket at the same time, which speeds up your work and cuts down on wasted motion.

Most excavators have the joysticks positioned on armrests in the cab, right where your hands naturally rest. The left joystick and right joystick each control different functions, and the specific setup depends on which control pattern your machine uses. Modern excavators often let you customize button functions and even adjust how sensitive the controls feel, so you can set things up exactly how you like them.

ISO vs. SAE: Excavator Joystick Control Patterns

Here’s where things get interesting. There are two main excavator control patterns ISO, established by the International Organization for Standardization, and SAE, established by the Society of Automotive Engineers. The big difference between them is which hand controls what part of the machine.

ISO is the more common pattern and is often referred to as “CAT controls” (because it’s what CAT machines often use) or “excavator controls.” SAE is a US standard and is often referred to as “John Deere Controls” (because it’s what John Deere machines often use) or as “backhoe controls.”

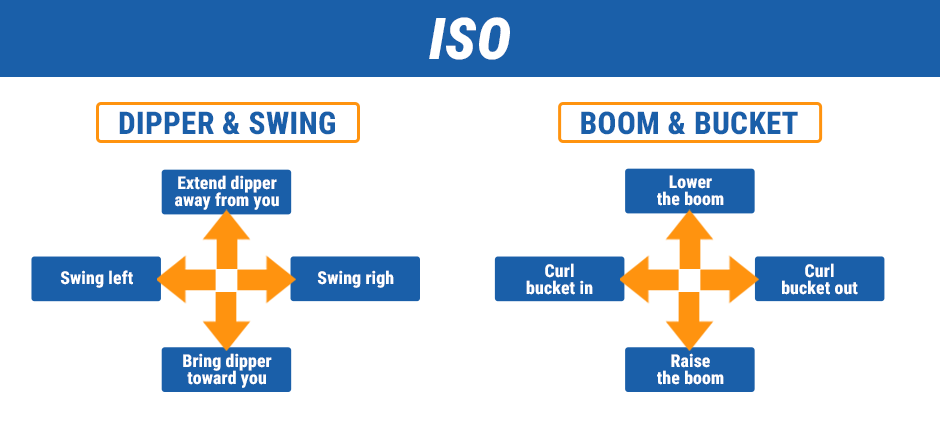

ISO Controls (CAT Pattern)

The difference between the two is that ISO controls use the right-hand lever to control the boom and bucket and the left-hand lever for the dipper (stick) and swing. With ISO controls, the movements feel pretty natural – when you want to bring the stick closer to you, you pull the left joystick back, just like you’d pull your own arm back.

Here’s how ISO breaks down:

- Left joystick left/right: Swings the machine left or right

- Left joystick forward/back: Extends or retracts the stick (dipper)

- Right joystick left/right: Curls the bucket in or dumps it out

- Right joystick forward/back: Lowers or raises the boom

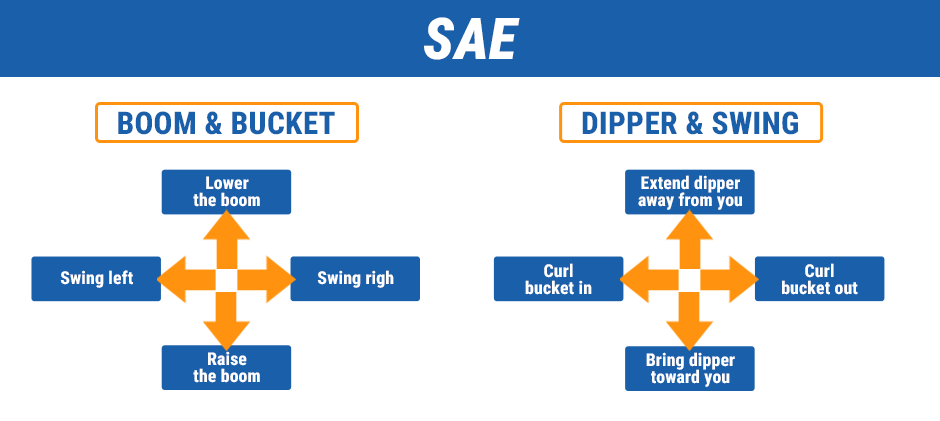

SAE Controls (John Deere Pattern)

The SAE pattern is different from ISO, using the left-hand excavator joystick for the boom and swing, and the right-hand joystick for the dipper and bucket. This pattern basically swaps which hand controls the boom and which hand controls the stick.

SAE pattern works like this:

- Left joystick left/right: Swings the machine left or right

- Left joystick forward/back: Lowers or raises the boom

- Right joystick left/right: Curls the bucket in or dumps it out

- Right joystick forward/back: Extends or retracts the stick (dipper)

Both control standards use the left-hand joystick for swing, so that’s one thing that stays the same no matter which pattern you’re using.

How to Use Excavator Joystick Controls?

Getting comfortable with the excavator joysticks takes practice, but once you get the hang of it, the movements become second nature. Let me walk you through how to actually operate these controls.

Getting Started

Before you enter the excavator, make sure the door is secure and locked to the side of the machine so you can use the handle to climb in safely and so the wind doesn’t blow it shut against you. Maintain three points of contact as you climb in. Once you are in the cab, follow these steps: Always put your seat belt on first.

After you’re buckled in, close the door and get familiar with where everything is. Turn the key to start the excavator. Check the display for error codes and ensure it has fuel. Engage the safety lock lever (the controls won’t work while it’s locked). That safety lock is there to prevent accidental movements when you’re getting in or out.

Basic Joystick Movements

Start by practicing each movement separately before you try combining them. Push the right joystick forward to lower the boom (or the left joystick if you’re on SAE controls). Pull it back to raise the boom. Move it left and right to control the bucket curl.

The left joystick (on ISO) controls your stick extension and swing. Push it forward to extend the stick away from you, pull it back to bring it closer. Move it left and right to swing the upper part of the machine.

Once you’re comfortable with individual movements, you can start combining them. This is where excavator work gets smooth and efficient. You might lower the boom while extending the stick and curling the bucket all at the same time to scoop up a load.

Digging with the Joystick

Then drop the dipper/stick and bucket all the way out until you are around one foot off the ground. Point the bucket teeth down, drop it to puncture the earth, and then curve the bucket in to dig and fill the bucket. Swing left (or right) to dump after raising the bucket five to six feet off the ground.

The key to good digging is smooth, controlled movements. Don’t jerk the joysticks around – that puts stress on the hydraulic system and makes your work sloppy. Instead, make gradual movements and let the machine do the work.

Switching Between ISO and SAE Control Patterns

On newer excavator models, there may be a lever to swap the control pattern, depending on your machine. This may be located under the floorboard in the cab or behind a panel. Some machines make switching even easier.

On modern Cat excavators, for example, Select the setting submenu, then the operator settings submenu, and click on operator inputs configuration. You will see five options: left joystick, right joystick, lever pattern, restore to factory setting and current configuration. You can change the pattern right from the monitor screen.

Many modern excavators and backhoes have the option to run on both SAE or ISO controls. Historically, however, backhoes typically ran on SAE and excavators ran on ISO.

One thing to know – switching patterns if you’re already used to one can be really tough. Changing patterns is like learning a different language. It’s really, really challenging. Once your muscle memory gets used to one pattern, the other one feels completely backwards. If you’re just starting out, pick one pattern and stick with it.

Safety Tips for Using an Excavator Joystick

Safety should always be your top priority when you’re running an excavator. Here are the key things to keep in mind:

Before You Start Operating

Conduct a pre-operation safety check before operating an excavator to ensure that everything is in working order and the machine is safe to use for you and those around you on the site. These safety checks also prolong the life of your machine and prevent minor issues from getting worse.

Check your hydraulic fluid levels and hoses for any leaks. Inspect the tracks or tires for damage or wear. Test all the safety systems, including the warning lights and emergency stop button. Make sure the backup alarm works – that thing can save lives.

During Operation

Keep your movements smooth and controlled. Practice feathering controls to stop smoothly rather than releasing joysticks abruptly. Smooth operation extends component life and maintains better load control when moving materials around obstacles or near property lines.

Always know what’s around you. When rotating the cabin, check the surroundings for obstacles or personnel and operate the joystick slowly. The swing function can be dangerous because the back of the excavator moves in the opposite direction from where you’re looking.

Watch your stability. Never work on slopes steeper than what your manufacturer recommends. Keep the bucket low when you’re driving the machine around. If you’re working on uneven ground, take it slow and be extra careful.

Know Your Limits

Don’t overload the bucket or try to lift more than the machine can handle. Every excavator has load limits, and pushing past them can cause the machine to tip over. That’s how people get seriously hurt or killed on job sites.

If abnormal sounds, vibrations, or malfunctions occur, stop operations immediately, troubleshoot, and resume only after ensuring safety. Avoid maintaining the same posture for long periods; take short breaks to prevent fatigue and maintain focus.

Advanced Excavator Joystick Features

Newer excavators come with some pretty cool features that make the joysticks even more useful. Let’s look at a few of them.

Joystick Steering

By using your left joystick to steer, you can control your attachment at the same time. There’s no need to move back and forth from travel controls to joysticks, cutting down on fatigue and keeping things on the go. This feature lets you drive the machine with the joystick instead of using the foot pedals.

To turn it on, you usually go into the settings menu and enable joystick steering, then assign which button on your joystick will activate it. When you press that button, push the joystick forward if you want to travel forward, right if you want to turn right, etc. You can also still use your thumbwheel to swing your attachment left and right.

Customizable Button Functions

Select the joystick you’d like to adjust. Each function will be matched with an image of its corresponding button or switch. Select each button and switch to assign or reassign a function. The configurations you assign are saved to your operator profile.

This means you can set up your joysticks exactly how you want them. If you prefer certain functions on certain buttons, you can make that happen.

Stick Steer and Cruise Control

On some Cat mini excavators, Stick steer puts the controls of the boom and blade in the palm of your hands via the right and left mini excavator joysticks. Operators can trench with the bucket using right-hand controls and can reposition the machine with the blade using left-hand controls. Because the stick steer makes trenching easier, operators can do more with less fatigue.

Cruise control works like it does in a car – it lets the machine keep moving forward or backward at a set speed, so you can focus on operating the boom and bucket without worrying about the travel pedals.

Excavator Joystick Common Mistakes to Avoid

Even experienced operators make mistakes sometimes. Here are the big ones to watch out for:

Not checking which control pattern the machine uses. If you hop into an excavator assuming it’s set up one way and it’s actually on the other pattern, you could swing the machine when you meant to move the boom. That’s dangerous.

- Moving too fast. When you’re learning, take your time. Slow, controlled movements are better than quick, jerky ones. Speed comes with practice.

- Forgetting about the safety lock. Make sure you engage that lock every time you park the machine or get out of the cab. If someone accidentally bumps a joystick while the lock is off, the machine could move and hurt someone.

- Overreaching with the bucket. The farther you extend the stick and boom, the less stable the machine becomes. Know your limits and don’t push it.

- Not adjusting the seat and controls. Take a few minutes to set up the seat so you’re comfortable and can reach everything easily. Your back will thank you at the end of a long day.

Maintenance Tips for Excavator Joystick Controls

Your joysticks take a beating over time, so a little maintenance goes a long way.

Check the joysticks regularly for any looseness or excessive play. If they feel sloppy or don’t return to center properly, that’s a sign something needs attention. Keep them clean – dirt and debris can get into the mechanisms and cause problems.

Look at the hydraulic lines and connections that link the joysticks to the rest of the system. Any leaks or damaged hoses need to be fixed right away. Hydraulic fluid under high pressure can be dangerous if it sprays out.

If your excavator uses electronic controls, make sure all the electrical connections are clean and tight. Corrosion on connectors can cause all sorts of weird control issues. These are exactly the issues FridayParts can help you tackle. We offer top-quality replacement joystick controllers that fit a wide range of brands and models. Shop now!

FAQs

Can I switch my excavator from ISO to SAE controls?

Yes, many modern excavators let you switch between control patterns. Some machines have a physical lever or valve you can flip, usually located under the floorboard or behind a panel in the cab. Newer models often let you change the pattern through the monitor screen in the settings menu. Check your operator’s manual to see if your specific machine has this feature and where to find the switch.

Which is better for beginners – ISO or SAE excavator joystick controls?

Most people recommend starting with ISO controls if you’re new to excavators. The movements feel more natural because they mirror how your arms work – when you want to bring something closer, you pull the stick toward you. That said, if you’ve got experience running backhoes, you might feel more comfortable with SAE controls since that’s what backhoes traditionally used. The “better” pattern really comes down to what you’re used to.

How long does it take to get good at using excavator joysticks?

For basic movements, you can get comfortable in a few hours of practice. But becoming smooth and efficient with combined movements – like scooping, lifting, and swinging all at once – usually takes several days to a couple weeks of regular use. Professional-level skill where you can work quickly and precisely without thinking about the controls might take months of daily operation. The key is consistent practice and starting with simple tasks before moving to more complex work.

Why do my excavator joysticks feel loose or sloppy?

Loose joysticks usually mean there’s wear in the linkages or the control valve itself. Over time, the bushings and pins that connect everything can wear out, creating play in the system. It could also be low hydraulic fluid or air in the hydraulic lines. This is something you want to get checked out by a mechanic because sloppy controls make precise work nearly impossible and can be a safety issue.

What’s the difference between excavator and backhoe controls?

There isn’t really a difference – both terms refer to the same ISO and SAE control patterns. Backhoes traditionally used SAE controls, which is why SAE is sometimes called “backhoe controls.” Excavators traditionally used ISO controls, so ISO is sometimes called “excavator controls.” These days, most modern machines of both types can run either pattern, so the old naming conventions don’t mean as much as they used to. The actual difference is just which hand controls the boom versus the stick.