If your equipment makes a strange humming noise while moving or under load, don’t ignore it; instead, pay close attention to when and where it occurs. Check promptly to see if it increases with driving speed or engine RPM. Recording these details will help you pinpoint the cause of the problem. Don’t ignore this issue to avoid more complex problems later.

Common Causes of Humming Noise in Heavy Equipment

The humming sound that gets louder with speed or load is often a sign of mechanical or hydraulic friction, caused by uneven wear, fluid aeration, or metal-to-metal contact.

Here are some frequent sources:

1. Wheel Hub or Planetary Bearings

Each hub supports massive weight and torque, often through tapered or spherical roller bearings in planetary gear sets. If lubrication breaks down, rollers pit and create a rhythmic humming that grows louder as the machine moves.

How to Confirm:

- Listen near each hub or use a mechanic’s stethoscope during slow travel.

- Lift the wheel or track and rotate by hand — roughness indicates bearing failure.

Fix:

- Replace worn bearings.

- Clean and pack the new ones with the correct high-pressure grease.

- Always torque retaining nuts to the OEM specification.

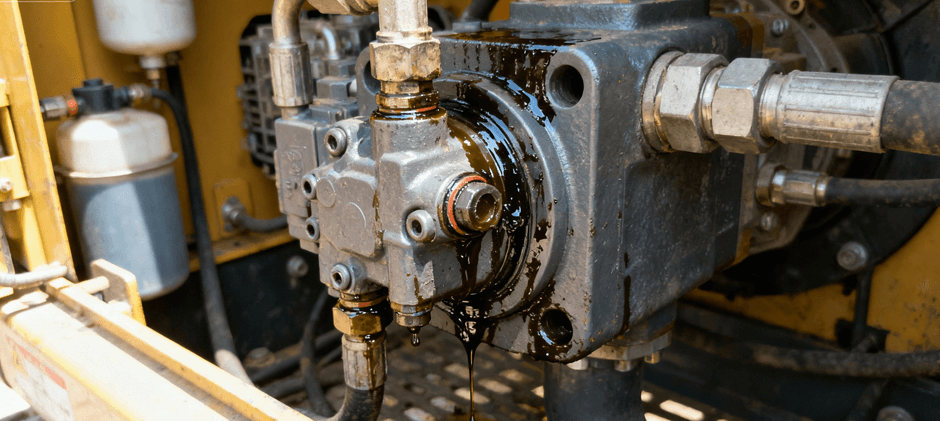

2. Hydraulic Pump or Motor Noise

Hydraulic pumps and motors, especially centrifugal and axial piston types, can generate a noticeable humming sound when cavitation or internal leakage occurs. Air bubbles or turbulent oil make the pump vibrate, causing a deep humming that increases with hydraulic load.

Possible Causes:

- Clogged suction strainer or restricted return filter.

- Air is entering through loose fittings or cracked hoses.

- Oil level too low or viscosity too high in cold conditions.

Fix and Prevention:

- Ensure oil meets temperature and viscosity requirements.

- Bleed air from the circuit after maintenance.

- Replace filters and check suction line seals regularly.

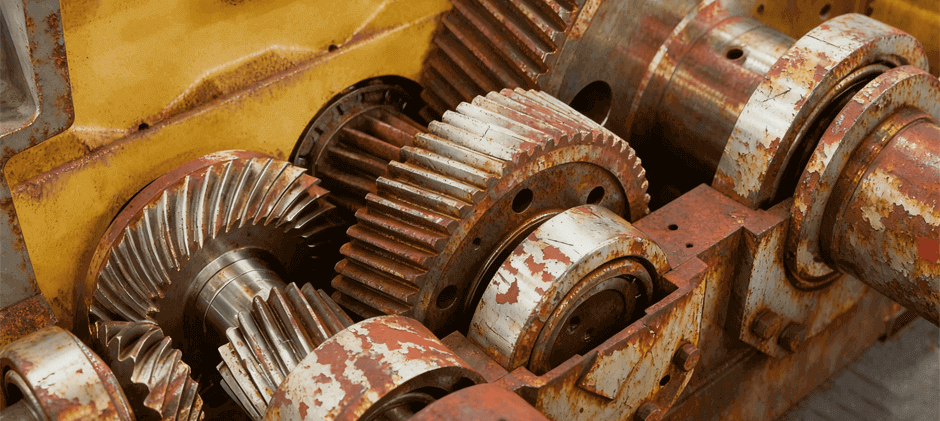

3. Transmission or Final Drive Gears

The drivetrain — including the torque converter, gearbox, and final drive assembly — transfers large amounts of torque through multiple gear stages.

When gear teeth wear, preload loosens, or oil level drops, these parts can whine or hum during travel.

Symptoms:

- Pitch rises with ground speed or throttle.

- Noise is strongest under acceleration or uphill travel.

- May vanish when stationary or idling neutral.

Fix:

- Check oil level and viscosity.

- Drain and look for metal particles in oil.

- Replace worn bearings or adjust backlash if abnormal gear wear is detected.

4. Cooling Fan Drive or Belt System

Belt-driven cooling fans, alternators, and air compressors can develop humming when idler bearings wear or belts lose tension. Unlike squealing belts, this sound is steady and proportional to engine RPM.

Fix:

- Inspect belt tension and pulley alignment.

- Spin each pulley by hand — rough rotation indicates bearing damage.

- Always replace the belt and tensioner together to avoid recurrence.

5. Hydraulic Hose or Pipe Resonance

Flexible hoses can act as sound chambers when the oil flow pulsates, especially when the pump displacement or relief valve setting changes rapidly. This resonance generates buzz or hum transmitted through the frame and cabin.

Prevention:

- Use proper hose clipping and damping sleeves.

- Isolate high-pressure lines with vibration mounts.

- Check that pump damping or orifice inserts are installed properly.

6. Axle Gear or Differential (for Articulated Trucks, Wheel Dozers, etc.)

In multi-axle systems, the differential or axle carrier can hum when gear contact patterns shift due to wear or incorrect preload. Incomplete shimming or oil contamination accelerates wear, producing a droning tone during constant speed travel.

Fix:

- Inspect for leaks, excessive backlash, and gear tooth pitting.

- Refill using gear oil meeting OEM EP (extreme pressure) spec.

- Rebuild the differential with matched gear sets if noise persists.

How to Diagnose the Humming Noise?

1. Determine When It Occurs

- During travel, only → drivetrain or hub bearings.

- During hydraulic operation → pump or valve.

- With engine speed → pulley, belt, or cooling fan.

2. Check Oil and Filter Condition

- Milky → air contamination

- Metallic glitter → gear or bearing wear

3. Use Acoustic Tools

- A mechanic’s stethoscope or portable vibration sensor helps locate the source.

- Compare left vs right hub, forward vs reverse drive.

How to Get Rid of the Humming Noise?

- Drain and replace contaminated oil or grease.

- Replace worn bearings, gears, or couplings.

- Tighten loose mounts and hydraulic fittings.

- Ensure correct oil viscosity and warming before operation in cold climates.

How to Prevent Humming Noise in Heavy Equipment?

1. Lubrication Management

Use OEM-specified oils and follow proper change intervals.

Monitor oil temperature and pressure. Overheated or oxidized oil loses film strength, increasing metal contact and vibration.

2. Clean Hydraulic and Drivetrain Systems

Dirt in oil accelerates wear. Always change filters as scheduled and seal filler ports during service.

3. Inspect Bearings and Mounts

During every 500-hour inspection, spin test rotating parts for roughness and verify the hub oil level.

4. Maintain Cooling and Belt Tension

Check fan drives monthly for smooth rotation. Misaligned pulleys cause both vibrations and cooling inefficiency.

Pro Tips for Mechanics

- Avoid diagnosing by ear alone — noises travel across the frame. Use isolation testing (e.g., one hydraulic function at a time).

- For suspicions of internal gearbox issues, measure the oil temperature difference between the left and right final drives. The hotter side often hides the root problem.

- After replacing bearings or gears, always perform break-in under light load to establish smooth contact surfaces.

Quick Recap

| Type of Source | Typical Frequency | Linked to |

|---|---|---|

| Hydraulic Pump Cavitation | Low–medium | Hydraulic flow/load |

| Gearbox or Final Drive Wear | Medium–high | Travel speed |

| Hub or Bearing Damage | Medium | Wheel rotation rate |

| Belt or Fan Issues | Medium–high | Engine RPM |

| Pipeline Resonance | Low | Hydraulic pulsation |

Conclusion

A steady humming noise in heavy-duty off-road equipment is not mere background sound — it’s an early warning of friction, wear, or flow imbalance.

By keeping systems properly lubricated, maintaining hydraulic cleanliness, and inspecting rotating components regularly, you can catch these issues early and prevent costly downtime. Whether you’re operating a wheel loader, dozer, haul truck, or excavator, remember: If the machine starts to hum, it’s telling you something — don’t make it sing louder