Getting your John Deere 1 or 2 Series tractor properly ballasted isn’t just about preventing wheelies—it’s about safety, performance, and protecting your investment. Whether you’re running a loader, backhoe, or heavy implements, the right ballast and tire setup makes the difference between a tractor that works efficiently and one that’s unsafe or tears up your yard.

This guide covers everything you need to know about ballasting your compact utility tractor, from tire pressure recommendations to wheel weight options and liquid ballast calculations. We’ll walk through the physics of why ballast matters, how much you need for different applications, and the common mistakes that can damage your John Deere tractor or create dangerous working conditions.

Why Ballast Matters for Your John Deere 1/2 Series?

The John Deere 1 Series (1023E, 1025R, 1026R) and 2 Series (2025R, 2032R, 2038R) are compact utility tractors designed for versatility, but that versatility comes with a challenge: these machines are relatively light compared to their lifting capacity. Your 1025R weighs around 1,500 pounds, but with a loader, it can lift 600+ pounds several feet in the air. Without proper ballast, simple physics tells you what happens—the back end comes up.

Proper ballast does four critical things for your tractor. First, it provides the counterweight needed to safely operate a loader without the rear wheels leaving the ground. Second, it improves traction for pulling implements like tillers, plows, and box blades. Third, it stabilizes the tractor when working on slopes or uneven terrain. Fourth, it reduces wheelslip and tire wear by keeping the weight distributed properly across all four wheels.

The challenge is finding the right balance. Too little ballast and you’re unsafe. Too much ballast and you’re compacting soil unnecessarily, wasting fuel, and putting extra stress on drivetrain components. The sweet spot depends on what you’re doing with your tractor and changes based on the implements you’re running.

What Does the 1/2 Series Weight Distribution Mean?

Your John Deere compact utility tractor has a specific weight distribution that affects how it handles and what ballast you need. Without a loader, these tractors are slightly rear-heavy by design—about 40% front, 60% rear. This distribution helps with traction when pulling implements. Add a loader, and that shifts dramatically toward the front, especially when you’re carrying a load in the bucket.

The 1 Series models (1023E, 1025R, 1026R) have operating weights between 1,400 and 1,650 pounds, depending on configuration. The 2 Series models (2025R, 2032R, 2038R) range from 1,500 to 1,900 pounds. These are dry weights without ballast, fluids, or implements. Once you add a loader, you’re typically adding another 350-450 pounds to the front of the tractor.

John Deere publishes ballast recommendations in the operator’s manual, but here’s the simplified version: with a loader, you want to add 75-100% of the maximum loader lift capacity as rear ballast. For a 1025R with a 300D loader (624 lb lift capacity), that means 470-624 pounds of rear ballast. For the heavier 2038R with a 260 loader (791 lb capacity), you’re looking at 593-791 pounds at the rear.

Tire Pressure Guidelines for 1 & 2 Series Tractors

Tire pressure is the most overlooked aspect of tractor setup, and it makes a huge difference in how your machine performs. The correct pressure depends on your tire type, what you’re doing, and the load you’re carrying. Get it wrong and you’ll experience poor traction, uneven tire wear, soil compaction, and a rough ride.

R4 Industrial Tire Pressures

Most 1 and 2 Series tractors come standard with R4 industrial tires—these are the tires with a shallow tread pattern that look almost like turf tires but with more aggressive lugs. R4 tires are designed for mixed use on lawns, gravel, and light dirt work.

| Tractor Model | Front Tire Size | Front PSI | Rear Tire Size | Rear PSI |

|---|---|---|---|---|

| 1023E, 1025R | 25×8.50-14 | 18-20 | 41×14.00-20 | 12-14 |

| 1026R | 25×8.50-14 | 18-20 | 41×14.00-20 | 12-14 |

| 2025R | 27×8.50-15 | 20-22 | 41×14.00-20 | 12-14 |

| 2032R, 2038R | 27×8.50-15 | 20-22 | 47×15.50-20 | 14-16 |

These pressures assume loaded tires with ballast and loader work. If you’re running unloaded tires and doing light work, you can drop the rear pressure by 2-3 PSI for a softer ride and better traction on turf. If you’re doing heavy loader work or working on hard surfaces, stay at the higher end of the range.

R1 Agricultural Tire Pressures

R1 ag tires have deep, aggressive lugs designed for maximum traction in soil. These tires are common on 2 Series tractors used for more serious agricultural work. They provide better grip but can tear up lawns and are noisier on pavement.

| Tractor Model | Front Tire Size | Front PSI | Rear Tire Size | Rear PSI |

|---|---|---|---|---|

| 2025R (Ag) | 8.3-20 | 16-18 | 13.6-16 | 12-14 |

| 2032R, 2038R (Ag) | 8.3-20 | 16-18 | 16.9-24 | 14-16 |

Ag tire pressures run lower than industrial tires because the deeper lugs need to flex to clean themselves and maintain traction. Running Ag tires at industrial tire pressures will give you a harsh ride and reduce the traction advantage.

R3 Turf Tire Pressures

R3 turf tires are designed to minimize turf damage and provide a smooth ride. These are less common on 1/2 Series tractors but are sometimes fitted to 1 Series models used primarily for lawn and property maintenance.

For R3 turf tires, run front tires at 14-16 PSI and rear tires at 8-10 PSI. The lower pressures spread the load over a wider contact patch and reduce compaction and turf damage. Don’t use turf tires for heavy loader work or ground engagement—they don’t have the traction or structural strength for those applications.

Rear Ballast Options: Weights vs. Liquid Fill

You have three main options for adding rear ballast: suitcase weights on a bracket, wheel weights, and liquid fill in the tires. Each has advantages and disadvantages, and many operators use a combination.

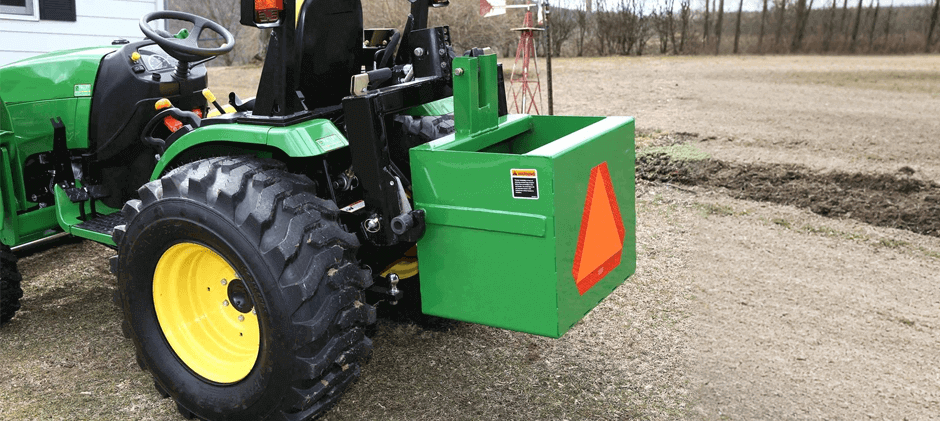

Suitcase Weights

Suitcase weights mount to a rear ballast bracket that bolts to the Category 1 three-point hitch. These weights typically come in 42-pound cast iron blocks that stack together. This is the most flexible ballast option because you can add or remove weight quickly without tools.

For John Deere 1/2 Series tractors, you’ll typically want 4-8 suitcase weights (168-336 pounds) as a baseline when running a loader. The exact number depends on your loader capacity and what you’re lifting. Start with the lower end and add more if you’re experiencing rear wheel lift or poor traction.

The advantages of suitcase weights are flexibility, easy adjustment, and the ability to remove them completely when doing three-point hitch work. The disadvantages are cost (they’re expensive), they take up three-point hitch capacity, and they can limit ground clearance. You also can’t use them with implements that mount to the three-point hitch.

Wheel Weights

Wheel weights bolt directly to the rear wheel hubs and add weight right where you need it—at the rear axle. John Deere offers cast iron wheel weights in various sizes, typically 35-70 pounds per wheel, depending on the model.

| Model | Wheel Weight Part Number | Weight Per Side |

|---|---|---|

| 1025R, 1026R | BM24456 | 52 lbs |

| 2025R | BM24456 | 52 lbs |

| 2032R, 2038R | BM25647 | 68 lbs |

Installing two wheel weights (one per rear wheel) gives you 104-136 pounds of ballast that doesn’t interfere with three-point hitch operation. This is a good base ballast that works with any implement configuration. The weight is positioned at the axle centerline, which maximizes its effectiveness as a counterweight to front-mounted loaders.

You can combine wheel weights with suitcase weights for heavy loader work. A common setup is wheel weights for everyday use, plus suitcase weights that you add when doing serious loading or working on slopes.

Liquid Ballast

Filling your rear tires with liquid ballast is the most cost-effective way to add significant weight. The standard formula is a mix of water and calcium chloride or RV antifreeze, filled to about 75% capacity (9 o’clock position when the valve stem is at 12 o’clock). This leaves room for air pressure while adding maximum weight.

For a 1025R with 41×14.00-20 rear tires, filling to 75% adds approximately 150 pounds per tire, or 300 pounds total. For a 2038R with 47×15.50-20 tires, you’re adding closer to 180 pounds per tire, or 360 pounds total. These are significant amounts of weight for minimal cost.

The advantages of liquid ballast are low cost, permanent weight low in the tire for stability, and no impact on implement clearance or three-point hitch capacity. The disadvantages are that the weight is permanent (can’t be quickly adjusted), it makes tire changes more difficult, calcium chloride is corrosive to wheels, and it adds significant weight that you carry even when you don’t need it.

Calculating Ballast Requirements

Here’s a practical approach to figuring out how much ballast you need. Start with the loader lift capacity from your operator’s manual. For a 1025R with a 300D loader, that’s 624 pounds at the pivot pins. Multiply that by 0.75 to get your minimum rear ballast (468 pounds) and by 1.0 to get your maximum safe ballast (624 pounds).

Now look at what you typically carry in the bucket. Most homeowner operations involve moving dirt, gravel, or firewood that weighs 300-400 pounds per bucket. If you’re regularly lifting the maximum capacity, the ballast is at the higher end. If you’re mostly doing lighter work, the lower end is fine.

Add up your ballast options: liquid-filled tires (300 pounds), wheel weights (104 pounds), and suitcase weights (variable). A common setup for a 1025R would be liquid-filled rear tires (300 lbs) plus 3-4 suitcase weights (126-168 lbs) for a total of 426-468 pounds. This gives you safe operation for most loader work while keeping the total weight reasonable.

For backhoe work, the equation changes. The backhoe adds significant weight to the rear (250-350 pounds, depending on model), which acts as ballast. However, you’ll want some front ballast—either a loaded bucket, front weights, or liquid in the front tires—to keep the front end from being too light when the backhoe is digging.

Front Ballast for Backhoe and Heavy Rear Implements

When you add a backhoe or other heavy rear implement, you shift the weight balance dramatically rearward. This can make steering difficult and cause the front wheels to slip or lose traction. Front ballast corrects this problem.

The easiest front ballast is simply keeping the loader bucket on and filling it with weight. A bucket loaded with sand, concrete blocks, or a home-made weight box provides easily adjustable front ballast. For a 1025R, 200-300 pounds in the bucket is usually sufficient when running a backhoe.

If you’ve removed the loader, you need another solution. Front suitcase weights are available that mount to brackets on the front of the tractor. These work similarly to rear suitcase weights but are less common. Alternatively, liquid ballast in the front tires adds 60-80 pounds per tire for 1 Series models and 75-100 pounds per tire for 2 Series models.

Another option is a home-made weight box that fits in the loader bucket mounting frame. Many owners build a steel box that bolts to the front of the tractor and can be filled with concrete, achieving 150-250 pounds of permanent front ballast without the expense of factory weights.

Ballast Setup by Common Application

Let’s look at specific ballast recommendations for the most common ways people use their 1 and 2 Series tractors. These are starting points—adjust based on your specific conditions and how the tractor handles.

Mowing and Light Property Maintenance

For mowing with a mid-mount or finish mower, you don’t need much ballast. The mower deck itself adds weight, and you’re not lifting or pulling heavy loads. Run tires at normal pressure, skip the liquid fill unless you do occasional loader work, and operate without suitcase weights. Wheel weights are optional but can improve traction on slopes.

Loader Work (General)

General loader work—moving mulch, dirt, gravel, firewood—requires moderate ballast. Fill rear tires with liquid (300 pounds for 1 Series, 360 pounds for 2 Series), add wheel weights (104-136 pounds), and carry 2-4 suitcase weights (84-168 pounds) for a total of 488-604 pounds. This handles most loader applications safely without excessive total weight.

Heavy Loader Work

If you’re regularly maxing out your loader capacity—moving large rocks, loaded pallets, or wet clay—go with maximum ballast. Liquid-filled rear tires, wheel weights, and 4-6 suitcase weights give you 550-700+ pounds of rear ballast. Make sure your tires are at maximum recommended pressure for the load.

Box Blade, Tiller, or Ground Engagement

Heavy pulling implements need more traction than a counterweight. Liquid-filled rear tires are ideal because they add weight low in the tire, where it improves traction the most. Run rear tire pressure at the lower end of the range (12-14 PSI for R4 tires) to increase the contact patch. Skip the suitcase weights if you need three-point hitch capacity, but wheel weights help without interfering.

Backhoe Operation

Backhoes add their own weight (250-350 pounds) plus the digging forces push the rear down, so you don’t need additional rear ballast. Instead, add 200-300 pounds to the front—either in the loader bucket or as front weights. This keeps the front wheels planted and maintains steering control.

Common Ballast Mistakes to Avoid

The most dangerous mistake is running a loader without adequate rear ballast. We see videos all the time of compact tractors flipping over backward because the operator lifted a heavy load without a counterweight. Front-end loader flips can cause serious injury or death—this isn’t optional, it’s a safety requirement.

Another common error is using only suitcase weights without liquid or wheel weights. Suitcase weights sit behind the rear axle on a moment arm, so they’re less efficient than weights at the wheels. You need more total weight to get the same counterbalancing effect, and the leverage effect can actually contribute to bouncing or instability on rough terrain.

Running incorrect tire pressure causes multiple problems. Overinflated rear tires reduce traction, give a harsh ride, and cause the center of the tire to wear faster. Underinflated tires can damage the sidewalls, cause uneven wear, and make steering heavy. Check your pressure monthly and adjust seasonally—tire pressure changes about 1 PSI per 10°F temperature change.

Don’t use water alone as liquid ballast unless you’re in a climate that never freezes. Pure water will freeze and can damage or destroy your tires and wheels. Always use calcium chloride (for non-freezing applications) or RV antifreeze (the safer option that won’t corrode wheels). Mix calcium chloride at 3.5 pounds per gallon of water for freeze protection to about 0°F.

Installing and Adjusting Ballast

Installing suitcase weights is straightforward—you need a rear ballast bracket that bolts to the three-point hitch mounting points. John Deere offers OEM brackets, or you can find aftermarket versions. The bracket typically holds 6-8 weights and has pins or brackets to secure them. Stack the weights evenly and make sure they’re secured so they can’t shift during operation.

Wheel weights bolt to the rear wheel hubs using the existing lug bolt holes. You’ll need longer lug bolts, which should come with the weights. Jack up the tractor, remove the wheel, bolt the weight to the hub, and reinstall the wheel. The weight goes between the hub and the wheel. This is a permanent installation that you typically don’t remove once installed.

Liquid ballast installation is best done by a tire dealer unless you have experience and equipment. The process involves breaking the bead, positioning the tire with the valve stem at 12 o’clock, filling to the 9 o’clock position (75% full), and then adding air. The liquid needs to be mixed correctly, and you need to know exactly how much to add. Most dealers charge $50-75 per tire for liquid fill, which is money well spent for proper installation.

Adjusting ballast seasonally makes sense for many operations. In winter, you might want maximum ballast for snow removal with the loader. In summer, you might reduce ballast for mowing to minimize compaction. Keep suitcase weights available to add and remove as needed, but leave liquid fill and wheel weights installed year-round.

Safety Guidelines for Ballasted Tractors

Never exceed the ballast recommendations in your operator’s manual. Too much weight stresses drivetrain components, increases stopping distance, and can damage the rear axle or transmission. John Deere specifies maximum ballast limits for a reason—respect them.

When operating on slopes, ballast becomes even more critical. Side slopes increase the risk of rollover, and rear slopes increase the risk of backward flips when using a loader. If you’re working on slopes steeper than 15 degrees (about a 3:1 ratio), add extra rear ballast and reduce the height to which you lift the loader bucket.

Always carry the loader bucket low when traveling—12 inches or less off the ground. A raised bucket raises the center of gravity and increases instability, especially on uneven ground. This is basic loader safety, but bears repeating because it’s frequently ignored.

Test your ballast setup in a safe area before doing serious work. Lift the loader to full height with a moderate load and see if the rear wheels stay planted. If you see any rear wheel lift, add more ballast immediately. Better to be over-ballasted than unsafe.

Frequently Asked Questions

How much does liquid ballast cost to install?

Professional installation typically costs $50-75 per tire, or $100-150 for both rear tires. The ballast solution itself (calcium chloride or RV antifreeze) costs another $30-50. Total investment is around $150-200 for liquid-filled rear tires, which is significantly cheaper than cast-iron weights.

Can I use windshield washer fluid for liquid ballast?

Windshield washer fluid works and won’t corrode wheels like calcium chloride, but it’s more expensive than RV antifreeze for the same freeze protection. RV antifreeze (the pink stuff rated for -50°F) is the best option—non-corrosive, safe, inexpensive, and effective. Never use automotive antifreeze (ethylene glycol)—it’s toxic and dangerous.

Should I ballast my 1025R if I only use the mower?

If you never use the loader and only mow, you don’t need ballast beyond what improves traction on slopes. Wheel weights might help with hillside mowing, but liquid fill and suitcase weights add unnecessary weight that compacts soil and wastes fuel. Ballast for the work you actually do.

How do I know if I have enough rear ballast?

Perform a simple test: with the parking brake off and engine running, raise the empty loader bucket to full height. If the rear wheels lift off the ground at all, you don’t have enough ballast. Then test with a typical load in the bucket. The rear wheels should stay firmly planted in both scenarios.

Can I use front ballast without a loader?

Yes, and you might want to if you’re running heavy rear implements. Front ballast improves weight distribution and traction when pulling ground-engaging implements. It also improves steering and prevents the front end from bouncing on rough terrain.

Proper ballast and tire setup transform your John Deere 1 or 2 Series tractor from a tippy, sketchy machine into a stable, capable workhorse. Take the time to ballast correctly for your applications, maintain proper tire pressure, and you’ll work more safely and efficiently. FridayParts carries John Deere tractor parts and accessories to keep your John Deere compact utility tractor running right. From maintenance items to upgrade components, we’ve got what you need at prices that make sense.