Your New Holland Boomer 40 hydraulic system powers everything from the transmission to the loader, three-point hitch, and power steering. Understanding the correct hydraulic fluid type, capacity, and service requirements prevents costly repairs and keeps your tractor performing at its best. This comprehensive guide covers everything you need to know about Boomer 40 hydraulic fluid service.

The Boomer 40 is New Holland’s popular compact utility tractor in the 37-40 horsepower range, part of the Boomer 33-47 series built for versatility and reliability. Like most modern compact tractors, it uses a common sump design where one hydraulic reservoir serves both the hydrostatic transmission and implement hydraulics. This simplifies service but makes proper fluid selection and maintenance even more critical.

Boomer 40 Hydraulic System Overview

The Boomer 40 uses an integrated hydrostatic transmission and hydraulic system with a shared fluid reservoir. This means one fluid handles transmission drive functions, three-point hitch operation, loader circuits, remote hydraulic cylinders, and power steering. When you service the hydraulic system, you’re servicing the transmission at the same time—they’re inseparable.

The system operates at pressures up to 2,900 PSI for implementing hydraulics, while the hydrostatic transmission operates at lower pressures optimized for smooth speed control. A variable displacement piston pump supplies fluid on demand, increasing flow when you raise the loader or operate the three-point hitch, and reducing flow during simple road travel to save fuel and reduce heat generation.

Understanding this integrated design is crucial: contaminated or degraded hydraulic fluid doesn’t just affect loader performance—it damages the transmission, steering system, and every hydraulic component simultaneously. Keep the fluid clean and fresh, and all systems benefit. Neglect it, and everything suffers together.

Hydraulic Fluid Capacity and Specifications

The total hydraulic/transmission fluid capacity for the New Holland Boomer 40 is approximately 10.5 gallons (40 liters). This includes the main reservoir, transmission case, hydraulic pump, all lines, cylinders, and the hydraulic filter. When performing a complete fluid change with filter replacement, plan on using 10-11 gallons to account for fluid trapped in components.

New Holland specifies NH 410B Hydraulic/Transmission Fluid for the Boomer 40. This is New Holland’s premium UTT (Universal Tractor Transmission) fluid, formulated specifically for integrated hydrostatic transmission and hydraulic systems. It’s a multi-viscosity fluid with additives for wet brakes, hydraulic pumps, and hydrostatic drives.

| Specification | Details |

|---|---|

| Total Capacity | 10.5 gallons (40 liters) |

| Drain & Refill Amount | 10-11 gallons |

| Specified Fluid | New Holland NH 410B |

| Alternative Spec | UTF/UTT meeting NH 410B specification |

| Viscosity Grade | Multi-viscosity (10W-30 equivalent) |

| Operating Temp Range | -20°F to 120°F |

You can use aftermarket universal tractor transmission fluids that meet the NH 410B specification, but verify compatibility explicitly. Look for fluids labeled as meeting New Holland 410B, CNH MAT 3505, or Hy-Gard J20D equivalent specifications. These fluids have the proper viscosity, friction modifiers, and anti-wear additives required for the Boomer’s hydrostatic transmission.

Why NH 410B Specification Matters

New Holland 410B fluid is engineered with a specific additive package that standard hydraulic oils lack. The friction modifiers are critical for wet brake and wet clutch operation—they prevent brake chatter, clutch shudder, and ensure smooth engagement. Standard hydraulic oil causes these components to grab and chatter, making operation uncomfortable and causing premature wear.

The anti-wear additives protect hydraulic pumps and motors operating at high pressures and speeds. Hydrostatic transmissions are particularly demanding because the hydraulic motor runs continuously under varying loads. Inadequate anti-wear protection causes pump and motor wear that shows up as whining noises, loss of power, and eventually complete failure.

The viscosity index of NH 410B fluid ensures it maintains proper thickness across temperature extremes. In winter, it flows easily for responsive cold-weather operation. In summer under heavy loads, it maintains adequate film strength to protect components. Standard hydraulic oils don’t have this temperature stability—they’re too thick when cold and too thin when hot.

The additive package also includes oxidation inhibitors that prevent the fluid from breaking down under heat and pressure, rust and corrosion inhibitors to protect internal components during storage, and foam suppressants that prevent aeration, which causes spongy hydraulic response and accelerates wear.

Service Intervals for Boomer 40 Hydraulic Fluid

New Holland recommends the initial hydraulic/transmission fluid and filter change at 50 hours for the Boomer 40. This first service is critical—it removes break-in contaminants from new gears, pumps, bearings, and seals, wearing in together. These microscopic metal particles accelerate wear if left in the system beyond the break-in period.

After the 50-hour initial service, change the hydraulic/transmission fluid and filter every 600 hours or annually, whichever comes first. Most homeowners and small farm operators reach the annual interval before 600 hours. Commercial operators or those running the tractor heavily may hit 600 hours in 6-8 months.

The “whichever comes first” rule exists because hydraulic fluid degrades over time, even when the tractor sits unused. Oxidation, moisture absorption, and additive depletion happen whether you’re operating the machine or not. One year is the maximum interval regardless of hours on the meter.

| Service Point | Initial Interval | Regular Interval | Severe Service |

|---|---|---|---|

| Hydraulic/Trans Fluid & Filter | 50 hours | 600 hours / Annual | 400 hours |

| Hydraulic Filter Only | As needed | Inspect at 300 hours | 200 hours |

| Suction Strainer Cleaning | 50 hours | 600 hours / Annual | 400 hours |

| Fluid Level Check | Weekly | Every 25 hours | Daily |

If you operate in severe conditions—high ambient temperatures, sustained heavy loads, dusty environments, or continuous loader work—shorten the interval to 400 hours. Severe service accelerates fluid degradation and contamination, making more frequent changes necessary for component protection.

Hydraulic Filter Specifications and Part Numbers

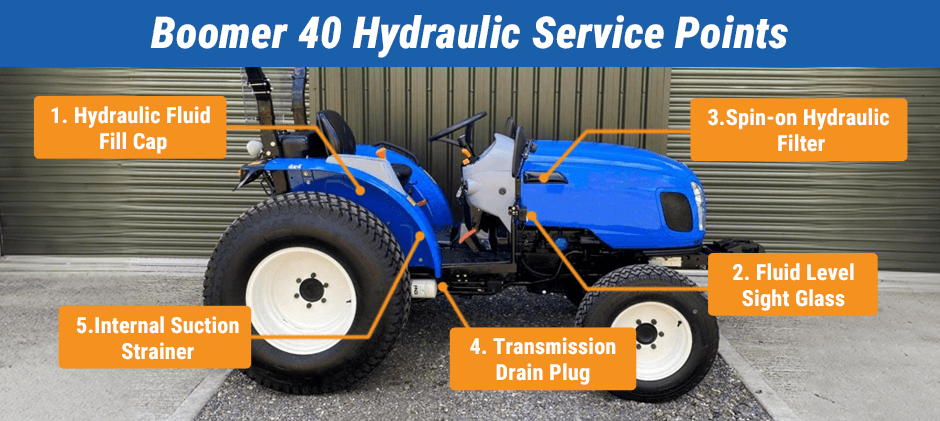

The Boomer 40 hydraulic system uses a spin-on cartridge filter and an internal suction strainer. Both need service when you change the hydraulic fluid. The main hydraulic filter is New Holland part number 84475542. This filter mounts on the outside of the transmission case on the right side of the tractor.

The hydraulic filter protects pumps, valves, cylinders, and the transmission from contamination. It filters particles down to 10-15 microns, removing the contaminants that cause component wear. Change it every time you change the hydraulic fluid—reusing an old filter defeats the purpose of fresh fluid.

The suction strainer is inside the hydraulic reservoir and filters fluid as it enters the pump. This coarse screen catches larger particles before they reach the main filter and pump. It’s often overlooked during service, but a clogged suction strainer starves the pump of fluid, causing cavitation, noise, heat, and damage.

| Component | Part Number | Replacement Interval | Function |

|---|---|---|---|

| Hydraulic Filter | 84475542 | Every fluid change | Protects system components |

| Suction Strainer | 84257511 | Clean at every service | Pre-filters pump inlet |

| Hydraulic Fluid | NH 410B | 50 / 600 hours | Full system capacity |

| Transmission Filter (if separate) | Check manual | Per service schedule | Some configurations only |

Quality aftermarket filters are available from FridayParts at better prices than dealer parts. Our filters meet or exceed OEM specifications with quality filter media and construction that protects your hydraulic system without the markup.

Checking Hydraulic Fluid Level

Check your Boomer 40 hydraulic fluid level weekly during regular use or before each use if you operate sporadically. The sight glass or dipstick location varies slightly by model year, but it’s typically on the right side of the transmission case near the hydraulic filter.

To check properly, park on level ground, shut off the engine, and wait 5 minutes for fluid to drain back into the reservoir. Check the sight glass—the level should be between the minimum and maximum marks. If you have a dipstick rather than a sight glass, pull it out, wipe it clean, reinsert it fully, and pull it again to read the level.

A low fluid level indicates a leak somewhere in the system. Check around the hydraulic filter, all hydraulic line connections, cylinder rod seals, three-point hitch lift arms, and the transmission case for wet spots, drips, or accumulated dirt (dirt sticks to leaked hydraulic oil). Address leaks immediately—running low damages the pump and causes overheating.

Don’t overfill the reservoir. Too much fluid causes foaming as gears and components churn through the excessive level. This aeration creates air bubbles that make hydraulic operation spongy and erratic, reduce pressure and flow, and accelerate fluid breakdown. Keep the level in the middle of the sight glass or at the full mark on the dipstick.

Step-by-Step Hydraulic Fluid Change Procedure

Changing hydraulic fluid on your Boomer 40 is a manageable DIY project if you have basic mechanical skills and tools. Block off 3-4 hours for the complete job, including cleanup. Work when the tractor is warm but not hot—warm fluid drains faster but won’t burn you.

Tools and Materials Needed

- 10-11 gallons of NH 410B hydraulic/transmission fluid

- New hydraulic filter (84475542)

- Large drain pan (15+ gallon capacity)

- Socket set and wrenches

- Oil filter wrench

- Clean rags and shop towels

- Funnel

- Safety glasses and gloves

- Catch containers

Draining the System

Run the tractor for 10 minutes to warm the fluid, then park on level ground and shut off the engine. Engage the parking brake. Locate the drain plug on the bottom of the transmission case—it’s typically a large bolt on the lowest point of the case toward the rear.

Position your drain pan under the plug. The plug usually requires a 19mm or 22mm wrench or socket. Remove it carefully—the warm fluid will flow quickly at first. Let the system drain completely, which takes 20-30 minutes for 10+ gallons of fluid.

While draining, cycle the loader and three-point hitch several times with the engine off to push additional fluid from cylinders and lines into the reservoir to drain. This helps remove old fluid more completely. Move the range selector through all positions to drain the transmission thoroughly.

Replacing Filters

While fluid drains, remove the old hydraulic filter using an oil filter wrench. It’s on the right side of the tractor, usually easily accessible. Expect some fluid to spill when you remove it, so have rags ready. Clean the filter mounting surface on the case.

Before installing the new filter, fill it about 1/3 full with clean hydraulic fluid and coat the rubber gasket with fluid. This pre-fills the filter to reduce air in the system and lubricates the gasket for proper sealing. Thread the filter on by hand until the gasket contacts the mounting surface, then tighten an additional 3/4 turn by hand. Don’t use the filter wrench to tighten—hand tight plus 3/4 turn is correct.

The suction strainer requires removing the hydraulic reservoir cover or access panel. Consult your operator’s manual for the specific procedure on your model year. The strainer typically pulls straight out. Clean it thoroughly with solvent, inspect for damage, and reinstall. If it’s damaged or won’t clean completely, replace it.

Refilling and Bleeding

Once everything has drained and filters are replaced, reinstall the drain plug with a new copper or aluminum crush washer if you have one. Tighten the plug to spec (typically 30-40 ft-lbs)—snug but not over-tight, which can strip the aluminum case threads.

Fill the hydraulic reservoir through the filler opening on top of the transmission. Use a clean funnel to prevent contamination. Pour slowly to avoid spilling—10 gallons is a lot of fluid. Fill until the sight glass shows mid-level or the dipstick reads full, then stop and prepare to bleed air from the system.

Start the engine and let it idle. Don’t rev it—just let it idle. Slowly move the range selector through all positions—forward, neutral, reverse—holding each position for 10 seconds. This circulates fluid through the transmission and begins purging air.

With the engine still idling, slowly operate the three-point hitch up and down through the full range 5-6 times. If you have a loader, slowly cycle it through full range—lift, dump, lower, curl—5-6 times. Move slowly to give air time to escape without causing foaming.

Shut off the engine and wait 10 minutes for air bubbles to rise out of the fluid. Recheck the fluid level—it will have dropped as fluid fills filters, lines, valves, and cylinders. Add fluid to bring the level back to the full mark. Start the engine again, operate all hydraulics, and check for leaks around the filter and drain plug.

What’s Hydraulic Fluid Condition

Monitoring hydraulic fluid condition between service intervals helps you catch problems early. Fresh NH 410B fluid is amber or light brown and transparent. As it ages and accumulates contaminants, it darkens to brown but should remain relatively clear.

Pull a fluid sample periodically using a clean turkey baster or fluid extraction syringe through the dipstick tube or filler opening. Put a few drops on a clean white paper towel and examine it. You’re looking for several warning signs that indicate problems.

Black or very dark opaque fluid indicates severe overheating, oxidation, or contamination. This fluid has broken down and no longer protects components adequately. Change it immediately, regardless of hours or time since the last change.

Milky or cloudy fluid means water contamination. This usually comes from condensation in the reservoir, a damaged seal allowing coolant to enter, or operating through deep water that entered through breather vents. Water destroys hydraulic pumps and causes rust throughout the system. Drain contaminated fluid immediately, identify and fix the water source, flush the system, and refill with fresh fluid.

Metallic particles visible in the fluid or on the drain plug magnet indicate wear inside the transmission, hydraulic pump, or motors. Some fine metallic dust is normal, especially after the break-in period. Larger particles, chunks, or lots of metallic material mean significant wear is occurring. Change the fluid and filter immediately and monitor closely. If the problem continues, you need a professional diagnosis.

The burnt smell indicates the fluid has been severely overheated, breaking down the base oil and additives. This happens from operating with a low fluid level, sustained heavy loads in high temperatures, or restricted hydraulic filters, causing excessive pressure drop. Change the fluid and investigate the cause of overheating.

Common Boomer 40 Hydraulic Problems

Most hydraulic problems trace back to the fluid. Always start by checking the fluid level, its condition, and the filters.

- Sluggish or Weak Performance: Slow lifts and a struggling three-point hitch are usually caused by low/degraded fluid or clogged filters, which reduce hydraulic pressure and flow.

- Noisy Hydraulic Pump: Whining or grinding sounds indicate cavitation, where the pump is starving for fluid. This results from a clogged suction strainer, low fluid, or air leaks. Address this immediately to prevent pump destruction.

- Transmission Slipping/Hesitation: In sensitive hydrostatic transmissions like the Boomer 40’s, this is often due to low, contaminated, or incorrect fluid (e.g., using motor oil instead of the specified NH 410B). A complete fluid drain and refill with the correct type is necessary.

- Overheating System: A hot oil smell and sluggish operation after extended use point to overheating. This is caused by a clogged filter, the wrong fluid, or sustained heavy loads in high ambient temperatures.

- Erratic Three-Point Hitch: If the hitch drifts, moves jerkily, or fails to hold its position, it likely indicates air in the system, contaminated fluid, or a worn control valve. Bleeding the system can remove air, but persistent issues may point to internal wear that requires professional service.

Preventing Hydraulic System Problems

Maintain clean fluid by changing it on schedule and using proper filtration. When adding fluid between changes, pour directly from sealed containers through a clean funnel. Never reuse drained fluid—even if it looks clean, it contains contaminants and depleted additives. Keep the area around the filler cap clean before opening to prevent dirt from falling into the reservoir.

Avoid mixing different brands or types of hydraulic fluid. If you’ve been using genuine New Holland NH 410B and want to switch to an aftermarket equivalent, do a complete drain and refill rather than topping off. Different additive packages can be incompatible and may not blend properly, potentially causing foaming, seal swelling, or reduced performance.

Watch for leaks and repair them promptly. A small seep at a cylinder rod seal or hydraulic line fitting becomes a major leak that leaves you stranded in the field. More importantly, leaks allow dirt to enter the system—dirt sticks to leaked oil on external components, and when you push components like cylinders, that contamination gets pulled past seals into your hydraulic system.

Operate the tractor properly to minimize hydraulic stress. Don’t stall the loader against its relief valve for extended periods—this generates tremendous heat that breaks down fluid rapidly. Don’t drop the three-point hitch from full height with implements attached—the shock loads stress components and cause seal damage. Smooth, deliberate operation extends component life and reduces maintenance.

Store the tractor properly to prevent moisture contamination. If you’re storing for extended periods, run the tractor before storage to circulate fresh fluid through the system, and store with the hydraulic reservoir full to minimize air space where moisture can condense. Consider adding a desiccant breather cap to the reservoir to prevent moisture from entering through the vent.

Cold Weather Hydraulic Considerations

NH 410B fluid is formulated for cold-weather operation with good flow characteristics down to -20°F, but extremely cold temperatures still affect performance. Below 0°F, even multi-viscosity fluid thickens and flows slowly until it warms up. Let the tractor warm up for 5-10 minutes before operating hydraulics in freezing weather.

During warm-up, operate hydraulic functions gently and slowly to circulate fluid and generate heat without stressing cold, stiff seals and components. Don’t immediately lift heavy loads or operate at maximum speed in extreme cold—let the system warm gradually through light operation.

If you regularly start and operate in sub-zero temperatures, consider installing a transmission/hydraulic heater. These bolt-on heaters warm the fluid before starting, improving flow and reducing wear during cold starts. Some models use engine coolant heat, while others use electric heating elements powered by block heater circuits.

Don’t store the tractor with the loader raised or the three-point hitch up in cold weather. As the fluid cools and contracts, it creates negative pressure in cylinders that can draw air past seals or pull contamination past rod seals. Store with all cylinders retracted—loader down, three-point hitch down, remote cylinders retracted.

Alternative Fluids and Compatibility

While New Holland specifies NH 410B fluid, several alternative fluids meet the same specifications and perform equivalently. John Deere Hy-Gard J20D is functionally equivalent to NH 410B and widely available. Kubota Super UDT2 also meets similar specifications and works in the Boomer 40.

Several aftermarket fluid manufacturers produce universal tractor transmission fluids meeting NH 410B specifications. Look for fluids explicitly stating compatibility with New Holland 410B, CNH MAT 3505, or Case/New Holland hydraulic systems. Brands like Traveller, TSC, and others offer competitively priced alternatives.

When selecting alternative fluids, verify they meet these requirements: suitable for wet brakes and wet clutches, appropriate viscosity for hydrostatic transmissions (typically 10W-30 equivalent multi-viscosity), anti-wear protection for hydraulic pumps and motors, and a temperature range suitable for your operating conditions.

Don’t use fluids not specifically designed for integrated tractor hydraulic systems. Standard hydraulic oil (AW32, AW46) lacks friction modifiers and proper viscosity. ATF is too thin and breaks down quickly under hydraulic pressures. Motor oil has the wrong additive package and viscosity. These substitutes cause immediate performance problems and long-term damage.

Frequently Asked Questions

Can I use John Deere Hy-Gard in my Boomer 40?

Yes, John Deere Hy-Gard J20D (low viscosity) is functionally equivalent to NH 410B and works perfectly in the Boomer 40. Many operators use Hy-Gard because it’s widely available at farm stores. Just make sure you’re using Hy-Gard J20D (low viscosity), not regular J20C Hy-Gard, for best performance in the hydrostatic transmission.

How do I know if I have the right amount of fluid after a change?

After changing fluid and bleeding the system, the sight glass should show fluid level in the middle third of the glass, or your dipstick should read full with the tractor on level ground and engine off after sitting for 5 minutes. If the level is low, add fluid in small amounts and recheck until the proper level is achieved.

What causes hydraulic fluid to foam?

Foaming results from overfilling (gears churn through excessive fluid), air leaks in the suction side of the system, wrong fluid type, or contamination with incompatible fluids. Check the fluid level first—if it’s above the full mark, drain to the proper level. If the level is correct, look for air leaks at pump seals, suction lines, or the suction strainer seal.

Can I extend the 600-hour service interval?

Not recommended without professional fluid analysis. While 600 hours may seem conservative, hydraulic fluid degradation accelerates under heat and pressure. The annual time limit exists because fluid degrades even when not in use. For expensive hydraulic repairs, fresh fluid is cheap insurance. If you want to extend intervals, implement an oil analysis program that tests fluid condition every 300 hours.

Why does my Boomer 40 hydraulic system seem weaker after a fluid change?

This usually indicates air trapped in the system. Bleed the system more thoroughly by operating all hydraulic functions slowly and repeatedly. Start the engine, let it idle, and cycle the three-point hitch 10-15 times, pause 5 minutes, then repeat. Do the same with loader functions if equipped. Air should purge within the first hour of operation.

Proper hydraulic fluid service keeps your New Holland Boomer 40 operating reliably for thousands of hours. Use the correct fluid, change it on schedule, maintain the proper level, and address problems early. FridayParts stocks quality New Holland replacement parts for your Boomer tractor at prices that make sense. From hydraulic filters to service kits, we’ve got what you need to maintain your New Holland properly without dealer markup.