Your machinery’s productivity mostly depends on the engine. However, few engine issues are more serious—or more dreaded—than a rod bearing failure. That deep knocking sound echoing from your engine block? It’s not something to ignore. Left unchecked, it can turn into a full rebuild or total engine loss.

This guide is designed for off‑road machinery owners who want to understand, diagnose, and confidently fix rod bearing issues. You’ll learn what rod bearings do, the warning signs of failure, how replacement works, and how to make smart OEM vs. FridayParts aftermarket part choices that keep costs under control.

What Exactly Is a Rod Bearing?

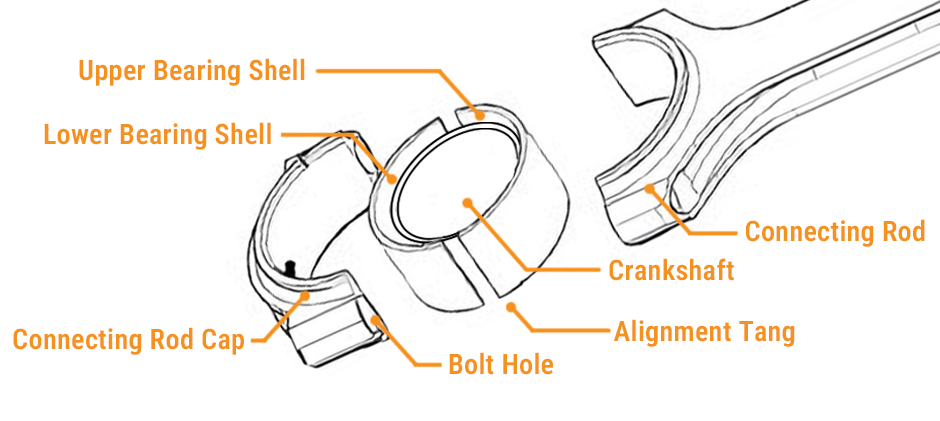

Inside every heavy‑duty diesel engine, rod bearings play a critical role. They’re precision metal shells, split into two halves that cradle the crankshaft journals at the “big end” of each connecting rod. Their mission? To provide a smooth, low‑friction surface that allows the connecting rod to spin around the crankshaft at high speed—without metal‑to‑metal contact.

A thin film of pressurized engine oil keeps these surfaces separated. Lose that film, and friction wins. The result is the distinct, rhythmic knock no machinery owner wants to hear.

Rod Bearings vs. Main Bearings: The Critical Difference

| Feature | Rod Bearings | Main Bearings |

|---|---|---|

| Location | Between the connecting rod and the crankshaft journal | Between crankshaft and engine block saddles |

| Function | Allow each piston’s rod to rotate freely around the crank | Support and align the crankshaft inside the block |

| Oil Flow | Receive pressurized oil through crank passages | Feed oil directly to the crankshaft and then to the rods |

| Quantity | One set per cylinder | Several across the crankshaft’s length |

Quick Tip: If you’re tracking noises or oil issues, understanding which bearing type is affected helps narrow your troubleshooting dramatically.

Why Rod Bearings Fail in Heavy Machinery

Off‑road and construction engines live under punishing conditions—heat, dust, shock loads, and long hours. Here are the most common culprits behind rod bearing damage:

- Lack of Lubrication: Low oil level, a weak pump, or incorrect viscosity can starve bearings. Without that oil film, the bearing overheats and “welds” to the crankshaft.

- Oil Contamination: Dirt, metal particles, or coolant leaks mix into your engine oil and embed in bearing material, scoring both bearing and crank surfaces.

- Engine Overloading or Lugging: Operating at low RPM under heavy load squeezes out oil film and adds stress—especially on hard‑working excavators or loaders.

- Corrosion and Chemical Breakdown: Extended oil intervals or diesel contamination create acidic conditions that pit bearing surfaces.

- Improper Assembly: During rebuilds, reversed caps, uneven torques, or dirty surfaces can cause immediate bearing failure after start‑up.

Early Warning Signs of Rod Bearing Problems

Catch these symptoms early, and you can save the crankshaft—and your wallet. For more detailed symptoms, you can read Rod Bearing Failure: 7 Warning Signs You Can’t Ignore.

- Deep Knocking Sound: A heavy rhythmic thump that changes with RPM, unlike the lighter valve‑train tick.

- Low or Fluctuating Oil Pressure: Worn bearings increase oil clearance, bleeding pressure.

- Metallic Sheen in Oil or Filter: Inspect drained oil and cut open the filter—silver or copper specks indicate bearing metal.

- Warning Lights: A low‑oil‑pressure or CEL light triggered by knock sensor detection.

Pro Tip:

If you observe multiple symptoms, stop running the engine immediately. Continuing to operate can turn a repairable bearing job into a full bottom‑end rebuild.

Step‑by‑Step Overview: How to Replace Rod Bearings

These steps summarize the process mechanics followed. Always confirm torque specs and procedures from your machine’s service manual.

- Safety First: Park securely, chock wheels, disconnect batteries.

- Drain Fluids: Remove engine oil and coolant.

- Remove the Oil Pan: Gain access to the crankshaft and connecting rods.

- Unbolt Rod Caps: Work one cylinder at a time to keep parts matched.

- Inspect the Crankshaft: Check journals for scoring or out‑of‑round wear.

- Install New Bearings: Clean surfaces, lubricate with assembly lube, and align bearing tangs properly.

- Torque to Specification: Follow the manufacturer’s pattern and values (many bolts are torque‑to‑yield).

- Reassemble: Reinstall the oil pan and components, then refill fluids.

- Prime the Oil System: Avoid dry starts by pre‑lubing wherever possible.

- Test Run: Confirm oil pressure, listen for abnormal noises, and monitor temperature.

While skilled owners can handle light rebuilds, rod bearing replacement usually requires a certified mechanic—especially on heavy‑equipment diesels like a Komatsu, Caterpillar, Cummins, or Perkins engine.

Rod Bearing Replacement Costs: OEM vs. FridayParts

Rod bearing replacement costs depend on labor and parts.

| Source | Description | Estimated Cost (6‑Cyl Set) |

|---|---|---|

| OEM (Dealer) | Genuine manufacturer bearings, perfect fit, often available only through dealers. | $250 – $700 + |

| FridayParts Aftermarket | Engineered to meet or exceed OEM specs. Excellent fit at a lower cost. | $80 – $250 |

- Labor Costs: Expect 8 – 20 hours, depending on engine access. At typical rates ($100–$200/hr), total labor can reach $1,000–$4,000 +.

- Budget Insight: Using FridayParts quality aftermarket bearings can reduce total repair costs by 20–40 % without sacrificing performance—money you can redirect toward critical downtime support or preventive maintenance.

Keep Your Off‑Road Engine Working Hard

A failed rod bearing doesn’t have to sideline your business for weeks. The key is early detection, accurate diagnosis, and using reliable components when you rebuild.

FridayParts offers premium aftermarket bearing sets and engine components for off‑road powerhouses like Caterpillar, Komatsu, Cummins, Perkins, Kubota, and more—all tested for the extreme duty cycles of construction, agricultural, and mining operations.

- Precision manufacturing that meets OEM tolerances

- High‑strength materials for diesel compression loads

- Global inventory and fast shipping for minimal downtime

Don’t let an engine knock end your project schedule. Find Heavy‑Equipment Rod Bearing Sets at FridayParts!

Key Takeaways for Off‑Road Machinery Owners

- Rod bearing health = engine longevity.

- Lack of lubrication is the #1 cause of bearing failure.

- When replacing, inspect the crankshaft—and never reuse damaged bolts.

- FridayParts aftermarket bearings offer the best price‑performance ratio.

Keep this guide bookmarked as your off‑road engine maintenance reference—and get your machine roaring back to life with confidence.