Coolant (also called antifreeze or radiator fluid) is very important in engine cooling systems. It can help cool the engine in summer and prevent freezing in winter, keeping the engine at the right temperature all the time. So, on the dashboard, when the low coolant light comes on, don’t ignore it! That could cause big trouble with the engine. Then what should we do about this situation? Let’s take a look below.

What Does the Low Coolant Light Mean?

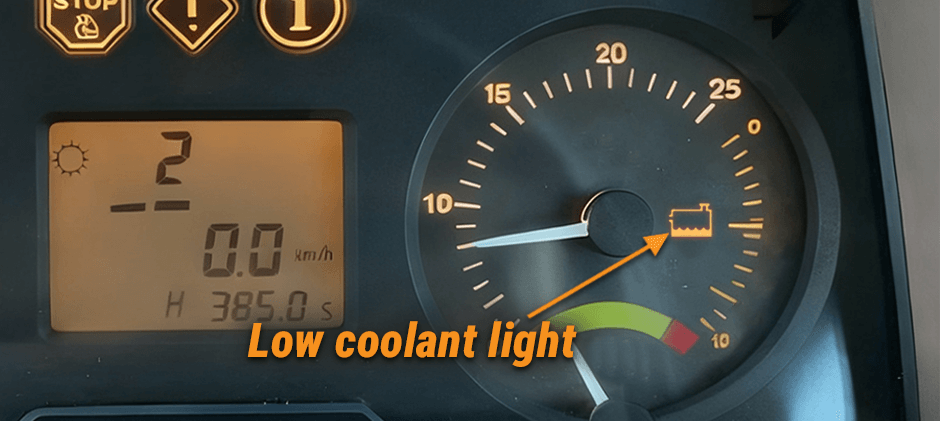

The low coolant level warning light (usually a wavy yellow or orange square icon) is actually the machine reminding you: there is not enough coolant. It can be treated as an early warning sign. Off-road equipment generates high heat when the engine is working, and the coolant’s job is to take that heat away. If there is too little coolant, there is no way for the system to cool down properly, and the engine will overheat quickly.

Once this warning light is ignored, the consequences can be serious— the cylinder head can be deformed, the gasket can burn out, and in severe cases, the engine can “get stuck”. So see it light up, don’t pretend you didn’t see it.

How the Low Coolant Light Works?

To figure out this warning light, you first have to know how it works. The low coolant warning light is actually triggered by a small device called the coolant level indicator. This sensor is usually packed in a coolant expansion tank (also called the reservoir or overflow tank).

It works simply: the coolant volume in the tank is monitored all the time. Once the liquid level falls below the pre-set point, the float or electronic probe will signal the Electronic Control Unit (ECU), which will light the warning light on the dashboard.

The purpose of this system is not to remind you again if problems such as these occur, but to give you an early warning. It will tell you before the engine temperature really rises, “coolant may be low”, so that you can stop, check, and repair in time, so as not to turn a minor problem into a major fault and shut down the entire unit.

What Are the Symptoms of Low Coolant?

Although the low coolant warning light is the most direct reminder, sometimes there can be a problem with the sensor, or you just want to check it out in advance. Being able to judge for yourself at this point whether the coolant is low is an important skill for the operator.

- Rising Temperature Gauge: This is the most obvious signal. If the pointer of the temperature needle runs towards “H” or even into the red zone, it means that the engine has started to overheat, and too little coolant is usually the main reason.

- A Distinct, Sweet Smell: The coolant has a special sweetness, like syrup. If you smell this around the machine, especially if it’s hot, it’s almost certain that there’s a leak.

- See Liquid on the Ground: After stopping the machine, see if there is any green, pink, blue or yellow liquid on the ground. If there is, it’s coolant. In addition, it can also be checked whether there is a colored hard shell formed near the hose, radiator, and water pump, which means that the coolant is slowly leaking.

- Poor Cabin Heater Performance: Warm air is not hot. If your machine has a cab, the heater uses hot coolant to warm the air. If the heater suddenly blows cold air, or the effect becomes worse, it may be that there is too little coolant or air has entered the system.

- Engine Overheating and Automatic Shutdown: Many machines now have a protection system that automatically reduces power or shuts down directly once the temperature is too high. At this point, you must stop the machine immediately for inspection, because that is the machine’s “self-rescue”.

An engine can suffer permanent damage in just a few minutes of running without sufficient coolant. The temperature gauge is your last line of defense; the coolant light is your first.

Why Is the Low Coolant Light On?

The cooling system would have been sealed. Normally, no coolant would have been lost. If the coolant indicator light is on, it means the coolant ran where it shouldn’t have been.

External Leaks

This is when the coolant really leaks out of the system and goes under the machine or something. In an environment like a worksite, this is the most common reason.

- Broken Hose: The hose will harden and become brittle over time, which can easily crack if it expands and contracts too much with heat. It may also be broken by vibration, friction or collision. Sometimes it’s just that the clamp is loose and it leaks.

- Radiator Leaks: Radiators are affected by dust, stones, vibration and pressure all year round. The heat sink is easily broken, and the inside may also start to leak due to corrosion or cracks.

- Water Pump Leakage: There is a sealing ring inside the water pump, which will age over time. The most typical manifestation is that the small hole at the bottom of the water pump (called the “drainage hole”) has stable small water droplets, which is a signal that the seal is about to fail.

- Gasket Aging: For example, there are gaskets in these parts of the thermostat shell and oil cooler. As the gasket ages and deforms, coolant will slowly seep out.

Internal Leaks

This is way more dangerous—coolant’s leaking right into the engine itself. You gotta deal with this right now.

- Blown Head Gasket: That gasket seals the little channels for coolant and oil between the engine block and cylinder head. If it breaks, coolant can leak into the engine’s cylinders or mix with the oil. If it gets into the combustion chamber? You’ll see thick white smoke coming out of the exhaust—smells kinda sweet too. If it mixes with the oil? Check the oil dipstick or the oil filler cap—you’ll find this milky, coffee-colored gunk.

- Cracked Cylinder Head or Engine Block: That’s a total disaster, usually from the engine overheating really badly before or a flaw when it was made. Unlike a head gasket, fixing it costs way more.

Evaporation from Overheating

If the engine overheats for other reasons, such as a broken cooling fan or a stuck thermostat, the coolant may boil. The radiator cover will discharge the coolant in the form of steam in order to release the pressure. As a result, the coolant level drops and the warning light comes on. However, be aware that the real problem at this point is not the leakage, but the engine overheating at the beginning.

What to Do When the Low Coolant Light Is On?

Don’t panic and don’t keep working when you see the low coolant light on.

Stop Immediately

As soon as the lights came on, they immediately stopped the heavy-duty work and drove the machine to a safe and flat place, away from the construction area. Let the engine idle for a minute or two, let the coolant circulate, the temperature stabilize, and then turn off. This avoids “hot soak” damage caused by a sudden shutdown.

Wait Until It Cools Down Completely

Never turn on the tank cover while the engine is still hot! The cooling system was stressed, and opening it rashly could spurt out scalding steam and coolant, and the scald was severe. You have to wait until the engine cools down before you do it, usually for an hour or so.

Checking the Level

After it cools down, find the coolant expansion tank, which is usually a translucent plastic pot with “MIN” and “MAX” scales on it. See if the liquid level is lower than the lowest line. If so, it is basically certain that the coolant is insufficient.

Add the Correct Fluid

This step is critical. Wrong is worse than no.

- Most Recommended: OEM-quality Coolant.. There are different types of coolants used in heavy equipment (such as OAT, NOAT, P-OAT). You need to check the manual to confirm the model. Don’t judge by color. The color is unreliable. The different types mix together and react chemically, turning into a gum that blocks the waterways and radiators.

- Temporary Emergency: If you don’t have the right coolant on hand and you have to operate the machine to the maintenance area, you can temporarily add distilled water. Don’t use tap water or mineral water; it will build scale. Remember, this is only a stopgap measure; change to regular coolant as soon as possible after use.

Find the Real Reason

Filling up is just an emergency and does not mean the problem is solved. A normally sealed system will not be devoid of coolant. Check if there is any leakage, dripping, or if the oil turns milky white, or if the exhaust gas emits white smoke, etc. Only when you find the root cause can you really fix it.

In Conclusion

The low coolant light is a reminder of potential coolant leakage, overheating, or evaporation. Once it lights up, it says it’s time to check the cooling system. If the low coolant light is always going wrong, FridayParts has replacement warning lights and cooling system parts, which can directly match various brands and models, easy and easy to install!

FAQ

Can you operate without coolant?

Never run an engine without coolant—it’ll mess it up bad in minutes. No coolant means engine parts get super hot fast. Metal stuff like pistons swells up. They can get stuck in the cylinders. That warps the cylinder head or even cracks the engine block. Repairs cost a ton. Lots of times, you’ll have to replace the whole engine.

Why is the coolant level tank full, and the light on is showing “coolant level low”?

The sensor is bad or overheating, meaning it’s just running too hot. Take it to a repair shop and let them look at it. I wouldn’t recommend you ignore it or forget about it, though. This could be serious or just a simple fix, but I wouldn’t keep operating it, especially if it’s overheating, then you could blow a head gasket sooner or later.