If your diagnostic tool shows DTC P0017, that’s not a warning you can afford to ignore. This code signals a timing correlation problem that—if untreated—can lead to severe mechanical damage.

In this guide, FridayParts walks you through what P0017 means, how to diagnose it efficiently, and what to do if you’ve already replaced the timing components but the P0017 code still won’t clear.

What Does Code P0017 Mean?

Definition: “Crankshaft Position – Camshaft Position Correlation (Bank 1, Sensor ‘B’)”

In simple terms, this means your engine’s crankshaft and exhaust camshaft are not synchronized.

Imagine the crankshaft as the drummer in your equipment’s “engine orchestra,” while the camshaft is the guitarist—it must play perfectly in rhythm for your machine to perform. When the Engine Control Module (ECM) detects they’re out of sync, it sets the P0017 code.

For heavy-duty diesel engines, this can cause:

- Loss of power and slow response under load

- Rough idle or stalling at low speeds

- Increased fuel consumption

- Hard starting or long cranking

- Poor engine brake performance is affecting safety on slopes

Common Causes of P0017 in Heavy Equipment

1. Incorrect or Contaminated Engine Oil

- Low oil level restricts the VVT (Variable Valve Timing) system.

- Wrong viscosity HDEO (Heavy-Duty Engine Oil) mismatches OEM specs.

- Contaminated oil blocks oil flow to the solenoids or phasers. Learn more in our guide on when and how to change your engine oil and filter.

Clogged or Failing VVT Solenoid (Oil Control Valve)

- Stuck solenoids can cause a permanent timing delay.

- Contamination or sludge is the main culprit—especially in dusty worksites.

Damaged Sensors or Wiring

- Faulty camshaft/crankshaft position sensors feed incorrect timing data. Learn about the 6 signs of a bad camshaft position sensor and how to test it.

- Heat, vibration, and corrosion can damage connectors or wiring harnesses.

Mechanical Timing Failure

- Stretched timing chain/gears, failed tensioner, or stuck cam phaser.

- If internal timing slips even one tooth, the ECM immediately logs P0017.

How to Fix P0017: Step-by-Step Diagnostic Process

Follow these four steps before replacing high-cost components.

1. Check the Oil

- Verify level and condition.

- If oil appears thick, black, or overdue, replace it with OEM-spec HDEO and a quality filter.

- In many cases, fresh oil restores proper VVT operation.

2. Scan and Compare Data

- Use professional software (e.g., Cat ET, Cummins INSITE, or Perkins EST). If you’re working on a CAT machine, our Caterpillar fault codes list can be a useful reference.

- Review live data: compare desired vs. actual camshaft angle.

- Look for delay or sluggish response — that points to oil flow or solenoid issues.

3. Inspect and Test Electronics

- Test the VVT solenoid by energizing it (listen for a click) or commanding it via the diagnostic tool.

- Check cam/crank sensors and harnesses for heat damage or corrosion.

- Replace or repair any questionable wiring.

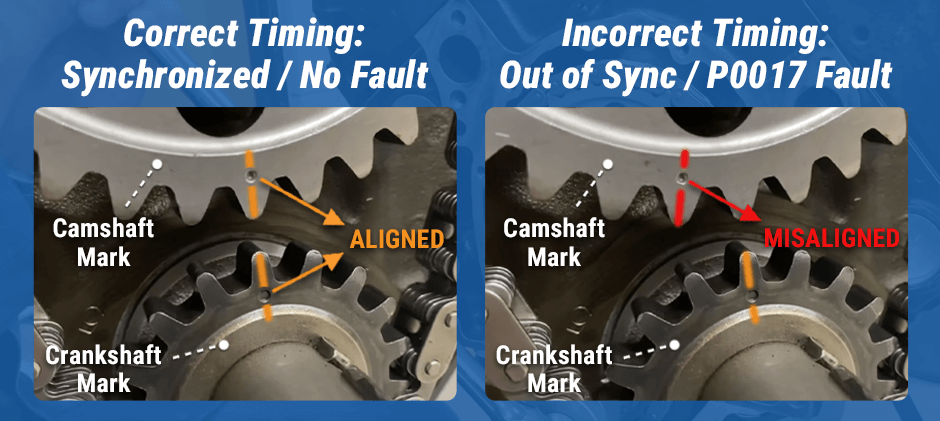

4. Check the Mechanical Timing

- Only after ruling out oil and electronics should you open the timing case.

- Verify timing marks at Top Dead Center (TDC).

- Replace stretched chains, worn gears, or failed tensioners as needed.

- Always torque components to factory specs.

What If the P0017 Code is Still On After Changing Timing Components?

It’s not uncommon—many technicians replace all timing parts only to find the P0017 code still active.

Here’s how to troubleshoot that situation.

Scenario: You’ve replaced the timing chain, tensioner, gears, and cam phaser. The engine runs smoothly with no misfire, but the check engine light remains on, and P0017 won’t clear.

Possible Reasons & Solutions:

| Cause | Check | Recommended Action |

|---|---|---|

| ECM hasn’t reset correlation data | The ECM stores adaptive values from the old timing setup | Perform a battery power reset (disconnect positive cable, link to ground for 5 min) or use a diagnostic tool to reset learned values |

| Residual diagnostic trouble code | Basic code readers may fail to clear permanent fault flags | Use a dealer-level scan tool to perform a “hard” code erase |

| Slight mechanical misalignment | Timing may still be off by 1°–2° due to a worn dowel pin, key, or cam phaser tolerance | Re‑verify timing mark alignment with service manual—precision matters |

| VVT Solenoid partially clogged | Even new systems can retain debris after repair | Remove and clean the solenoid with carb cleaner; verify movement and click on actuation |

| Sensor issue post‑repair | Sensor wiring may have been tugged or swapped during the timing job | Replace or test crankshaft/camshaft position sensors one at a time |

Pro Tip:

After any major timing work, always perform an ECM relearn procedure using your scan tool. This ensures the ECM properly recalibrates the correlation between camshaft and crankshaft sensors.

Preventing P0017 in the Future

- Stick to OEM Maintenance Intervals — Base them on engine hours, not just time.

- Always Use Genuine Replacement Parts — Cheap timing kits or VVT solenoids often fail prematurely.

- Use High‑Quality Fluids & Filters — Contaminated oil is the root cause of most P0017 cases.

- Regular Oil Analysis — Detects metal wear or contamination before failure happens.

At FridayParts, we supply reliable replacement components for all major heavy‑equipment brands—Caterpillar, Komatsu, Volvo, Cummins, John Deere, and more. All our timing kits, oil control valves, and sensors meet or exceed OEM standards, helping you restore precision and avoid repeated downtime.

Summary

If you see a P0017 code on your heavy‑duty equipment:

- Don’t panic.

- Follow a systematic diagnosis before replacing parts.

- If you’ve already changed timing components and the code remains, clear adaptations, verify mechanical alignment, and inspect solenoids and sensors again.

Downtime is costly—but with the right parts and the right process, you can keep your machines running strong and your projects on schedule.

Need high‑quality timing components or sensors?

Visit FridayParts.com to find the right parts for your engine, minimize downtime, and get back to work fast.