Ever fire up your heavy machine first thing in the morning, engine starts but won’t stay running? Yeah, it happens all the time out on construction sites or farms. There are tons of reasons why an engine starts up fine but can’t keep running. Fix it quick, and you’ll get back to work in no time. Let’s look at the most common causes for heavy equipment—and what you can do to fix ’em.

Common Reasons the Engine Starts But Won’t Stay Running

An engine needs three basic things to keep running: fuel, air, and compression (plus a spark that fires at the right time). If it starts up but dies right away? It’s getting those things for a second—then one of ’em cuts out fast. Let’s run through the most common troublemakers on heavy equipment:

1. Fuel System Issues

Most “start-then-die” problems come from the fuel system. The engine can fire up using the fuel already sitting in the lines—but it’ll die if fresh fuel can’t keep coming.

Clogged Fuel Filters

This is the most common and easiest thing to check. Your machine probably has at least two filters: a main one (that also traps water) and a second, finer one. If they get gunked up with dirt, debris, or even wax (when it’s cold out), fuel can’t flow through right. The engine might get just enough fuel to start from the pressure in the lines—but then it starves and shuts down fast.

Bad Fuel (Contaminated)

Off-road machines work in dusty, messy spots—so fuel getting contaminated is always a risk. Water in the fuel is a big problem here. Diesel is lighter than water, so water sinks to the bottom of the tank. That means it’s the first thing the engine sucks up. Engines can’t burn water, so after using up the good fuel in the injectors, it stalls instantly. Dirt, rust from storage tanks, even slime growing in diesel, can also clog up the whole system.

Weak or Broken Fuel Lift/Transfer Pump

This pump moves diesel from the tank to the injection pump. If it craps out, fuel supply dries up fast. A lot of the time, the engine fires up at first because there’s still some leftover fuel in the high-pressure injection pump. But that fuel burns out quickly—and the engine dies right away. On some machines, you’ll hear the lift pump making weird noises. If it’s really messed up? You won’t hear a thing from it.

Air in the Fuel Lines

If there’s even a tiny issue on the suction side of your fuel system, air can get sucked right in. Things like old, cracked fuel lines, or loose fittings—they’re the usual suspects. That air creates bubbles in the lines, so diesel can’t flow smoothly to the injectors. The engine burns fuel all wonky because of it. Result? It fires up, runs for a few seconds, then dies on you. This happens all the time right after you change the fuel filter—usually ’cause you didn’t bleed the air out of the system properly.

Failing Fuel Shut-Off Solenoid

Most diesel engines have a fuel shut-off solenoid. Flip the key off, and it cuts the fuel right away. If this little part goes bad, here’s the classic issue you’ll run into: It’ll pop open just long enough to get the engine started. But then it loses power, cuts the fuel supply cold, and the engine dies instantly. Looks like it’s dying for no reason at all—but the problem’s actually this tiny component.

2. Air Intake and Exhaust Issues

Engines need to breathe. If something blocks the air coming in or the exhaust going out, the engine will choke and die.

Blocked Exhaust (DPF or Muffler)

Newer diesel machines have a DPF (Diesel Particulate Filter) to catch soot. If that filter gets totally clogged and the machine can’t “burn off” the gunk (regeneration cycle fails), exhaust pressure builds up too high. The engine can’t push fumes out, so it chokes itself and dies shortly after starting. Older machines without a DPF? Same problem if the muffler caves in inside or gets packed with soot and junk.

Big Air Leak (After the Turbo)

On turbocharged engines, a huge leak in the pipes between the turbo and the engine’s intake manifold spells trouble. The engine’s brain (ECU) uses sensors to figure out how much fuel to mix with incoming air. A big leak messes up that calculation badly, and that can make the engine stall, especially when the turbo hasn’t had time to build pressure yet.

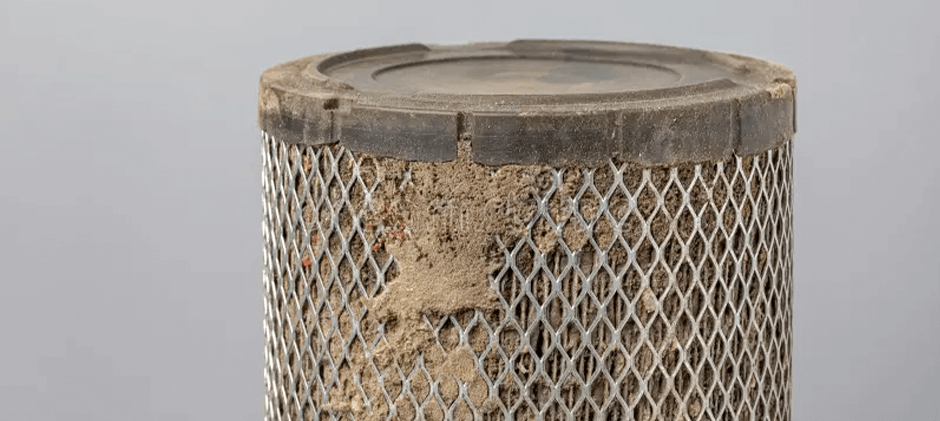

Totally Clogged Air Filter

A dirty air filter usually just robs you of power and makes a little black smoke. But if it’s totally plugged up? The engine might not run at all. This happens all the time on job sites—like when the machine sucks up a ton of dirt, mud, or even snow. The engine fires up and sputters for a second, but the blocked filter chokes it badly. No air can get in, so it dies out fast on its own.

3. Electrical and Sensor Malfunctions

Modern heavy machines run on a ton of sensors and a brain called the ECU to keep the engine going. Mess up anything here, and the engine dies in a flash.

Bad Alternator or Weak Battery

The engine needs lots of juice to run the ECU, fuel pump, and injectors. A battery might have enough charge to get the engine cranking—but if it’s totally drained, or the alternator isn’t charging it back up, voltage drops the second the engine starts. Once the voltage falls below what the ECU needs to work? It shuts down, and the engine stops dead.

Quick test: Jump-start the machine. If it runs fine with the jumper cables hooked up, but dies right after you disconnect them? Your alternator is definitely toast.

Failing Crankshaft or Camshaft Position Sensor

These sensors are super important. They tell the ECU exactly where and how fast the engine’s moving parts are spinning—critical info for timing fuel injection right. If one of these sensors acts up on and off, it might send a signal just long enough to start the engine. Then it craps out, the ECU loses track of timing, and cuts fuel immediately.

ECU Power Problems

The ECU itself needs steady power and a good ground connection to work. A loose power wire, a rusty ground strap, or a dying main power relay can make the ECU lose power seconds after the engine starts. That leads to a sudden shutdown.

Security System Glitch

Lots of new machines have anti-theft systems that need a coded key to run. If the system doesn’t recognize your key, or the anti-theft module messes up? It’ll let the engine start—but then cut fuel or ignition after a few seconds as a security trick. Check your dashboard for a flashing security light if this happens.

What to Do If the Engine Starts but Only Runs for a Short Time

Before you start ordering parts or calling a mechanic, follow a step-by-step routine to locate the problem.

Observe

- Check the dash: Any warning lights on? A check engine light, battery light, or system-specific warning can tell you exactly where to look. If you’ve got a digital display, look for fault codes.

- Listen: Did the engine shut off smoothly? That usually means an electrical or sensor issue (think fuel shut-off solenoid). If it sputtered and struggled before dying? It’s probably starving for fuel.

Basic Checks

- Fuel level: Sounds silly, but always check the tank. Fuel gauges lie all the time.

- Inspect the air filter: Pop open the filter housing and take a peek. Is it caked with dirt or junk?

- Check battery terminals: Make sure they’re clean and tight.

- Drain the water separator: Find your main fuel filter/water separator. Drain a little fuel into a clear jar. See water or chunks of gunk at the bottom?

Intermediate Diagnostics

- Change the fuel filters: If you’re not sure how old they are, just swap ’em out. It’s cheap maintenance and fixes this problem more often than not. After installing new ones, make sure to prime or bleed the system to get rid of air bubbles.

- Use a code reader: Plug a diagnostic tool into your machine’s port. Codes about fuel pressure, crankshaft/camshaft sensors, or throttle position? Those are huge clues.

- Check for fuel flow: Carefully loosen a fuel line fitting right before the injection pump (or at the secondary filter). Have someone crank the engine. You should see a steady squirt of fuel. Is it just a dribble or full of air bubbles? You’ve got a supply problem.

- Warning: Be super careful with high-pressure diesel. It can shoot right into your skin.

A Final Thought

If your heavy equipment engine fires up but dies right away, the most common reasons are fuel supply issues, wonky sensors, or electrical problems. Got the skills to fix it yourself? You can order most of the parts you need right here at FridayParts. We list all the compatible brands, models, and specs clearly for every part. Check out our huge selection of top-quality replacement parts—right now!