Your Kubota L3901 is built for decades of service, but achieving that longevity requires proper maintenance with the right fluids at the correct intervals. This comprehensive guide covers every fluid in your L3901—engine oil, hydraulic/transmission fluid, coolant, and fuel—with capacities, specifications, service intervals, and part numbers. Whether you’re performing your first 50-hour service or maintaining a tractor with thousands of hours, this is your complete resource.

The L3901 is part of Kubota’s Grand L Series, a range of compact utility tractors known for reliability and low operating costs. The L3901 specifically offers 37.5 gross horsepower from a 2.4-liter, 4-cylinder diesel engine with a gear-driven transmission and independent hydraulics. Understanding the fluid requirements for this system ensures you’re maintaining it properly and avoiding expensive repairs.

L3901 Engine Oil Specifications and Capacity

The Kubota L3901 uses a V2403-CR-T-E4 engine—a 2.4-liter, turbocharged, common-rail diesel with a diesel particulate filter (DPF). This engine requires specific oil to protect the emissions equipment and provide proper lubrication under the stress of turbocharging and diesel injection.

Engine oil capacity with filter is 8.5 quarts (8.0 liters). When changing oil, you’ll drain about 7.5-8 quarts, and the rest stays in the oil cooler, passages, and turbocharger. Always change the oil filter with every oil change to ensure you’re removing contaminants and refreshing the full oil supply.

Kubota specifies API CJ-4 or CK-4 diesel engine oil for the L3901. These specifications include low-ash additive packages that protect the DPF from clogging. Never use oil that doesn’t meet these specs—older API ratings (CI-4, CH-4) have higher ash content that damages emissions equipment.

| Specification | Details |

|---|---|

| Engine Oil Capacity | 8.5 quarts (8.0 liters) with filter |

| Required Specification | API CJ-4 or CK-4 |

| Viscosity (Standard) | 10W-30 or 15W-40 |

| Viscosity (Cold Climate) | 5W-30 (below 32°F) |

| Viscosity (Hot Climate) | 15W-40 (above 32°F) |

| Oil Filter Part Number | HH1C0-32430 |

For most users, 15W-40 diesel oil is the right choice. It provides excellent protection across a wide temperature range and is readily available. Use 5W-30 if you’re operating regularly in freezing temperatures for better cold starting and initial lubrication. Synthetic oils meeting CJ-4 or CK-4 specs are permitted and can extend drain intervals with proper oil analysis.

Engine Oil Service Intervals

Kubota recommends the first engine oil and filter change at 50 hours for the L3901. This break-in service removes metallic particles from new engine components wearing in together. These particles accelerate wear if left in the engine, so don’t skip or extend this first service.

After the initial 50-hour service, change engine oil and filter every 200 hours or annually, whichever comes first. The annual limit accounts for oil degradation from combustion byproducts, moisture contamination, and additive depletion that occur even when the engine isn’t running much.

If you’re operating in severe conditions—dusty environments, sustained high loads, frequent DPF regeneration, or extreme temperatures—Kubota recommends shortening the interval to 100-150 hours. Heavy loader work, continuous PTO operation, or commercial use qualify as severe service.

| Service Point | Initial Interval | Regular Interval | Severe Service |

|---|---|---|---|

| Engine Oil & Filter | 50 hours | 200 hours / Annual | 100-150 hours |

| Air Filter Inspection | 50 hours | Every 50 hours | Every 25 hours |

| Fuel Filter | 200 hours | 400 hours | 200 hours |

| DPF Service | As indicated | Per the warning light | Monitor frequently |

Watch your hour meter and calendar to track service intervals. Many L3901 owners in residential use hit the annual mark before reaching 200 hours. Commercial operations or full-time farmers often reach 200 hours in a few months. Service is based on whichever comes first.

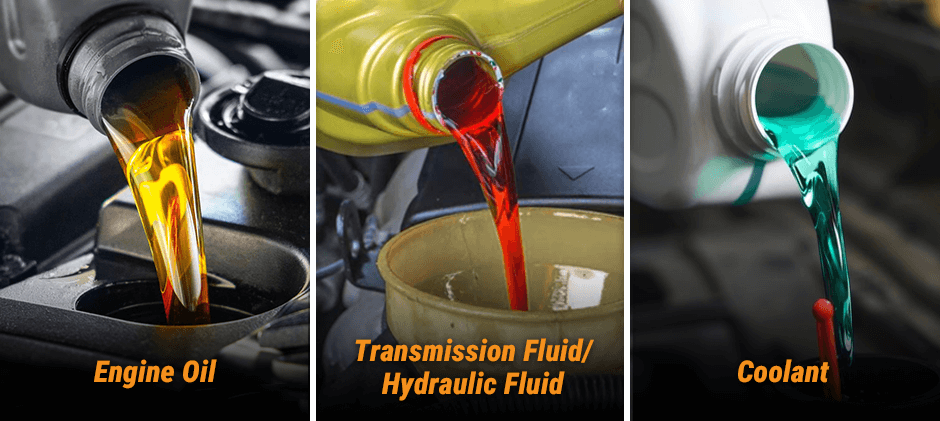

Hydraulic and Transmission Fluid Specifications

The L3901 uses separate reservoirs for transmission and hydraulic systems, unlike many tractors that use a common sump. This separation allows different fluid types optimized for each system’s specific requirements.

Transmission Fluid

The transmission oil capacity is 9.0 quarts (8.5 liters) for the gear transmission (standard on L3901). Kubota specifies Super UDT2 fluid for the transmission. This is Kubota’s universal dynamic tractor fluid, formulated specifically for wet brakes, wet clutches, hydraulic systems, and transmissions.

Super UDT2 meets multiple specifications: it functions as a transmission fluid, hydraulic oil, and wet brake fluid all in one. The additive package includes friction modifiers for smooth clutch engagement, anti-wear additives for gear protection, rust inhibitors, and foam suppressants.

| Specification | Details |

|---|---|

| Transmission Capacity | 9.0 quarts (8.5 liters) |

| Specified Fluid | Kubota Super UDT2 |

| Alternative Spec | Universal Tractor Fluid meeting UDT2 specs |

| Change Interval (Initial) | 50 hours |

| Change Interval (Regular) | 400 hours / 2 years |

You can use aftermarket universal tractor fluids that meet Kubota UDT2 specifications, but verify compatibility. Not all UTF fluids are created equal—some lack the proper friction modifiers for wet brakes or the viscosity index needed for cold-weather operation. When in doubt, use a genuine Kubota Super UDT2.

Hydraulic System Fluid

The hydraulic system capacity is 7.9 gallons (30 liters), including the reservoir, pump, lines, cylinders, and three-point hitch circuit. This is separate from the transmission system. Kubota specifies Super UDT2 for the hydraulic system as well, which simplifies fluid inventory—you use the same fluid for both systems.

The hydraulic system powers the three-point hitch, remote hydraulic circuits for implements, and the power steering. It operates at pressures up to 2,900 PSI, which demands high-quality fluid with robust anti-wear additives to protect the hydraulic pump and control valves.

| Specification | Details |

|---|---|

| Hydraulic Capacity | 7.9 gallons (30 liters) |

| Specified Fluid | Kubota Super UDT2 |

| Operating Pressure | Up to 2,900 PSI |

| Filter Part Number | HH1G0-32430 |

| Change Interval (Initial) | 50 hours |

| Change Interval (Regular) | 400 hours / 2 years |

Change the hydraulic fluid and filter at 50 hours initially, then every 400 hours or 2 years for regular service. The 400-hour interval is longer than some tractors because the L3901 has a high-quality filtration system, and Kubota Super UDT2 is a premium fluid with excellent oxidation stability.

Cooling System Specifications

The L3901 has a liquid-cooled engine with a pressurized cooling system. The total coolant capacity is 3.7 gallons (14.0 liters), including the radiator, engine block, and overflow reservoir. Kubota specifies a 50/50 mix of ethylene glycol antifreeze and distilled water.

Use antifreeze rated for diesel engines with supplemental coolant additives (SCA) appropriate for aluminum and cast iron cooling systems. The L3901 has an aluminum radiator and cast cast-iron engine block, so the coolant needs inhibitors compatible with both metals.

| Specification | Details |

|---|---|

| Coolant Capacity | 3.7 gallons (14.0 liters) |

| Coolant Type | 50/50 ethylene glycol & distilled water |

| SCA Required | Yes (diesel-rated antifreeze) |

| Change Interval (Initial) | 2 years or 400 hours |

| Change Interval (Regular) | Every 2 years or 400 hours |

| Radiator Cap Pressure | 14.2 PSI |

Never use plain water, even in warm climates. Antifreeze provides corrosion protection, lubricates the water pump, and raises the boiling point beyond what pure water achieves. The 50/50 mix protects to -34°F and raises the boiling point to about 265°F under pressure.

Check the coolant level weekly during heavy use or before each use for casual operation. The overflow reservoir should be between the minimum and maximum marks when the engine is cold. If you’re regularly adding coolant, you have a leak that needs immediate attention.

Fuel Specifications and Service

The L3901 requires ultra-low sulfur diesel (ULSD) with a maximum sulfur content of 15 ppm. This is the standard diesel fuel available at pumps throughout North America since 2006. Do not use biodiesel blends above B5 (5% biodiesel) without checking your warranty—higher biodiesel content can damage fuel system components.

The fuel tank capacity is 13.2 gallons (50 liters). The efficient 2.4-liter diesel engine gives you a full day’s work under most conditions. Fuel consumption varies with load, but expect approximately 1.5-2.5 gallons per hour under normal operation.

The fuel system includes a water separator and two fuel filters—a primary filter with a water separator and a secondary fuel filter. Water in diesel fuel is common and causes injection system damage, so the water separator is critical. Drain the water separator weekly or before each use by opening the drain valve at the bottom of the fuel filter canister.

| Service Point | Part Number | Service Interval |

|---|---|---|

| Fuel Filter (Primary) | HH1C0-32430 | 400 hours |

| Fuel Filter (Secondary) | HH1C0-32430 | 400 hours |

| Water Separator Drain | N/A | Weekly / Before use |

| Fuel Tank Cleaning | N/A | Every 800 hours |

Replace both fuel filters at 400-hour intervals or annually. Diesel fuel attracts and holds water, and over time, the fuel filter media degrades and loses its ability to separate contaminants. Don’t wait for symptoms—by the time you notice fuel delivery problems, you’ve likely damaged expensive injection components.

Air Filter Service and Specifications

The L3901 uses a two-stage air filtration system with a primary and secondary (safety) filter element. Clean, uncontaminated air is critical for diesel engine longevity—even microscopic dirt particles cause cylinder wear that shortens engine life.

The primary air filter (part number 59800-26110) is a dry paper element that captures most airborne contaminants. Inspect it every 50 hours or weekly during dusty conditions. Don’t wait for a restriction indicator to service the air filter—proactive maintenance prevents problems.

Clean the primary element by tapping it gently to remove loose dust, or use compressed air from the inside out at low pressure (30 PSI maximum). Replace the element when it’s damaged, won’t clean completely, or after 3-4 cleanings. The secondary filter (part number 59800-26120) is never cleaned—only replace it after every third primary filter change or if it becomes contaminated.

| Filter Type | Part Number | Service Action | Interval |

|---|---|---|---|

| Primary Air Filter | 59800-26110 | Clean or replace | Every 50-200 hours |

| Secondary Air Filter | 59800-26120 | Replace only | Every 3rd primary change |

| Pre-cleaner (if equipped) | Varies | Clean | Weekly in dust |

If you’re working in extremely dusty conditions—tilling, grading, hay work—inspect the air filter daily and clean or replace as needed. A clogged air filter reduces power, increases fuel consumption, and can allow unfiltered air past the seal if the element collapses under excessive vacuum.

Complete Service Schedule Overview

Here’s a comprehensive service schedule for your Kubota L3901 covering all fluids and filters. This table is your quick reference for staying on top of maintenance.

| Service Item | 50 Hr | 100 Hr | 200 Hr | 400 Hr | 800 Hr | Annual |

|---|---|---|---|---|---|---|

| Engine Oil & Filter | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Transmission Fluid | ✓ | ✓ | ✓ | ✓ | ||

| Hydraulic Fluid & Filter | ✓ | ✓ | ✓ | ✓ | ||

| Fuel Filters | ✓ | ✓ | ✓ | |||

| Air Filter (Inspect) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Coolant Check | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Coolant Change | ✓ | ✓ | Every 2 years | |||

| Grease All Fittings | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Battery Service | ✓ |

Annual service means “whichever comes first”—if you reach the hour interval before one year, service at that time. If you reach one year before the hour interval, service is at the annual mark. This ensures fluid doesn’t degrade from age, even if you’re not using the tractor heavily.

Fluid Change Procedures and Best Practices

Changing fluids on the L3901 is straightforward but requires attention to detail. Always work on level ground, use clean containers and funnels, and dispose of used fluids properly at a recycling center—never dump them on the ground or down drains.

Engine Oil Change Procedure

Run the engine for 5-10 minutes to warm the oil—warm oil flows faster and carries more contaminants. Park on level ground, shut off the engine, and let it sit for a few minutes to allow oil to drain back to the pan. The drain plug is on the bottom of the oil pan toward the front. Position your drain pan underneath and remove the plug with a 14mm wrench.

While the oil drains, remove the oil filter using a filter wrench. It’s located on the right side of the engine. Before installing the new filter, fill it halfway with fresh oil and coat the rubber gasket with oil. Thread it on by hand until the gasket contacts, then tighten an additional 2/3 to 3/4 turn. Don’t over-tighten.

Reinstall the drain plug and refill with 8.0 liters of fresh oil through the filler cap on top of the engine. Start the engine and let it idle for a minute, then shut it off and wait 5 minutes. Check the dipstick and add oil as needed to bring the level to the full mark. Check for leaks around the filter and drain plug.

Hydraulic and Transmission Fluid Change

The transmission drain plug is on the bottom of the transmission case, accessed from underneath the tractor. You’ll need a large drain pan—9 quarts is a significant amount of fluid. Remove the plug and let the transmission drain completely, which takes 15-20 minutes.

The hydraulic system drain is on the bottom of the hydraulic reservoir. Drain the hydraulic fluid into a separate container so you can inspect it for contamination. While draining, replace the hydraulic filter located on the right side of the tractor between the seat and rear axle.

Reinstall drain plugs and refill both systems through their respective fill ports. The transmission fill port is on the left side of the transmission case with a sight glass for checking the level. The hydraulic reservoir fill is under the right side of the operator platform. Fill to the proper level marked on the sight glass or reservoir.

Start the tractor and operate all hydraulic functions—three-point hitch up and down, remote cylinders in and out—to purge air and circulate new fluid. Shift through all transmission gears. Shut off the engine, wait 5 minutes, and recheck fluid levels. Top off as needed.

Common Fluid-Related Problems and Solutions

Dark or burnt-smelling engine oil indicates overheating or extended oil change intervals. Change the oil immediately and investigate the cause—clogged air filter, heavy loads, or low coolant can cause overheating. Black diesel oil is normal, but a burnt odor isn’t.

Milky or foamy hydraulic or transmission fluid means water contamination. This usually comes from a damaged seal allowing coolant into the system or condensation from temperature cycling. Drain the contaminated fluid immediately, identify and fix the source, and refill with fresh fluid. Water destroys hydraulic pumps and transmission components.

Excessive fuel in engine oil (diesel smell in oil, high level on dipstick) indicates injector problems or failed piston rings. This is serious—diesel fuel dilutes oil and removes its lubricating properties. Don’t run the engine. Have the injection system and compression checked by a qualified technician.

Coolant loss without visible leaks often means combustion gases entering the cooling system from a damaged head gasket. Symptoms include bubbling in the overflow reservoir, overheating, and white exhaust smoke. This requires professional repair—don’t ignore it.

Storing Your L3901: Fluid Considerations

If you’re storing your L3901 for more than a month, take steps to protect fluids and systems. Fill the fuel tank to prevent condensation, and add a diesel fuel stabilizer rated for long-term storage. This prevents fuel degradation, bacterial growth, and water separation.

Change the engine oil before storage rather than after. Used oil contains combustion acids and contaminants that corrode internal engine parts during storage. Fresh oil provides better protection. Run the engine for 5 minutes after the oil change to circulate fresh oil through all passages.

Check coolant freeze protection with a hydrometer or refractometer. Verify it’s adequate for your climate’s lowest temperatures. Top off the cooling system if needed, so you’re not storing with air space that allows corrosion.

Store the tractor with a full hydraulic oil reservoir and transmission filled to the proper level. This minimizes air space where moisture can condense. If you’re storing in an unheated building, consider adding a moisture absorber in the cab to reduce humidity.

Frequently Asked Questions

Can I use synthetic oil in my L3901?

Yes, synthetic diesel engine oil meeting API CJ-4 or CK-4 specifications is permitted and beneficial. Synthetics provide better cold-weather starting, improved high-temperature protection, and potentially extended drain intervals with proper oil analysis. Make sure the synthetic oil is specifically rated for diesel engines with DPF.

What happens if I use the wrong hydraulic fluid?

Using incorrect fluid can damage seals, cause brake chatter, reduce hydraulic performance, and void your warranty. The L3901 requires Kubota Super UDT2 or a compatible UTF meeting UDT2 specifications. Regular hydraulic oil or ATF doesn’t have the right additives for wet brakes and can cause expensive damage.

How do I know when to change fluids based on appearance?

Fresh fluids are transparent and colored (amber for oil, red for UDT2, green or orange for coolant). Dark, opaque, milky, or burnt-smelling fluids need immediate changing. Don’t wait for scheduled intervals if fluids show these symptoms—change them now to prevent damage.

Can I extend service intervals with synthetic fluids?

Only with oil analysis confirming the fluid is still serviceable. While synthetics last longer than conventional fluids, you can’t arbitrarily double intervals without testing. Contamination and fuel dilution still occur regardless of fluid type. For most users, following standard intervals with quality conventional fluids makes more sense than oil analysis programs.

What’s the difference between UDT and Super UDT2?

Super UDT2 is Kubota’s improved formula with better low-temperature flow, higher viscosity index, and improved additive package compared to the original UDT. Always use Super UDT2 in your L3901—it’s the specified fluid. Don’t use older UDT or UDT2 (without “Super”) as they don’t meet current specifications.

Proper fluid maintenance keeps your Kubota L3901 running strong for thousands of hours. Use the correct fluids, change them on schedule, and pay attention to the condition between services. FridayParts carries quality filters and maintenance parts for your Kubota models at competitive prices. From oil filters to hydraulic components, we stock what you need to maintain your Kubota properly without dealer markup. Quality parts, fair prices, fast shipping—that’s the FridayParts difference.