After learning the Common Bad Starter Symptoms, you also need to learn how to replace the faulty starter and the replacement cost. This guide explains how to locate, remove, and replace a starter motor, plus how to choose between repair, replacement, and cost‑effective parts for your off‑road machine.

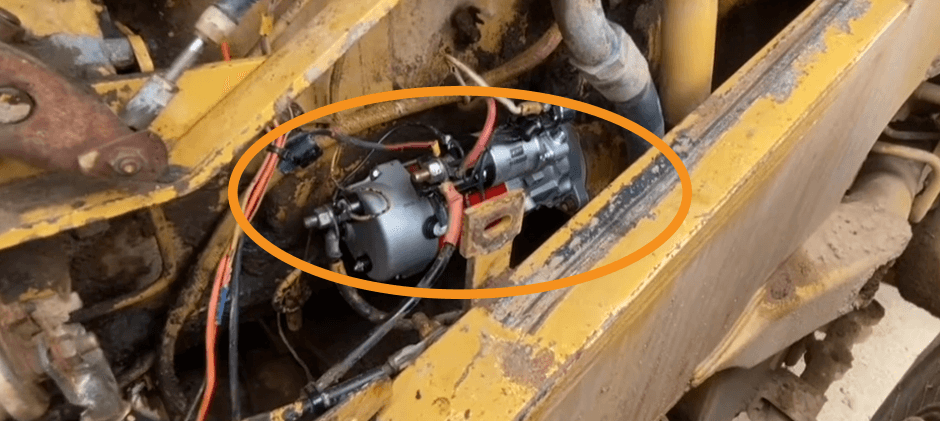

Starter Motor Location Diagram

Before you grab your tools, you need to find the starter motor’s exact location.

Where to Look

- Most heavy equipment starters are mounted to the engine block, right where the transmission or flywheel housing meets the engine.

- It’s usually low on the engine and easily visible.

What It Looks Like

A starter motor is a solid, cylindrical component with a smaller cylinder attached (the solenoid). You’ll see thick electrical cables connected to it.

Pro tip: Take a quick photo before removing anything. It’s safer and helps during reinstallation.

How to Replace a Starter Motor

Replacing a starter motor is similar across most machines. With basic hand tools and careful attention, you can do it confidently.

You’ll Need:

- Socket set & combination wrenches

- Ratchet with extensions

- Safety gloves & goggles

- Wire brush or sandpaper

- Jack and stands (if access is tight)

Step‑by‑Step Process

- Disconnect the Battery: Always start by removing the negative (-) terminal of the battery. This prevents shocks and short circuits.

- Gain Access: If parts block your view, carefully remove nearby guards or panels. Some machines may need partial lifting for access.

- Disconnect the Wires: The solenoid typically has two connections: A large cable from the battery (secured by a nut) & A smaller wire from the ignition switch (plug‑in or small nut). Label or photograph them for correct reconnection.

- Remove Mounting Bolts: Use your ratchet to remove the 2–3 bolts securing the starter to the engine. Support it with one hand—it’s heavier than it looks.

- Take Out the Old Starter: Gently slide or twist it free from the housing.

- Clean the Mounting Surface: Use your wire brush to clean dirt or corrosion from the contact points. Good grounding ensures a reliable start.

- Install the New Starter: Position the new starter and hand‑tighten bolts first, then secure them firmly. Avoid overtightening to prevent casting cracks.

- Reconnect the Electrical Wires: Attach all wires to their original terminals and tighten securely.

- Reconnect the Battery: Re‑attach the negative battery terminal.

- Test the System: Turn the key — you should hear a strong, smooth crank. If so, congrats — your machine is ready to go.

Repair vs. Replace — Which Is Better?

When downtime costs thousands per hour, there’s little room for guessing.

| Option | Best For | Pros | Cons |

|---|---|---|---|

| Repair | Minor electrical faults | Lower part cost | Time‑consuming, no full guarantee |

| Replace | Most starter issues | Fast, reliable, warranty‑covered | Slightly higher upfront cost |

Verdict:

In most cases, replacing the starter motor is faster and more cost‑effective — especially for operators aiming to minimize downtime and maximize reliability.

Starter Motor Replacement Cost

Labor

- DIY: Free (just your time).

- Technician: Usually 1‑3 hours of labor, depending on how accessible the starter is.

Parts

You have two main choices:

OEM Starter Motor

- Pros: Genuine brand part.

- Cons: Often 30–80% more expensive due to dealership markup.

FridayParts Aftermarket Starter Motor

Pros:

- Save 30–60% over OEM.

- Built to meet or exceed OEM standards.

- Designed for durability in off‑road environments.

- Includes a warranty for peace of mind.

Cons:

- No brand logo from the machine’s manufacturer — just better value.

For most owners, a FridayParts high‑quality aftermarket starter offers the best balance of cost, performance, and reliability.

Understanding repair costs is key to managing your machinery budget. For more insights, explore our other cost guides on topics like engine replacement, head gasket repair, and torque converter replacement.

Quick Recap

| Step | Action | Key Tip |

|---|---|---|

| 1 | Find the Starter | Photo reference helps later |

| 2 | Disconnect Battery | Always the first step |

| 3 | Remove Old Starter | Support its weight |

| 4 | Clean & Install New | Ensure tight grounding |

| 5 | Test | Listen for a strong, steady crank |

Final Note

A reliable starter motor is the first step toward keeping your machinery productive every day. Whether you operate excavators, dozers, tractors, or loaders, choosing the right starter motor ensures every start is strong, smooth, and dependable.

At FridayParts, we make it easy to keep your machines running:

- OEM‑quality starters engineered to meet or exceed factory standards

- Low prices that save you 30–60% compared to OEM parts

- Fast global shipping to over 150 countries

- 90‑day return and exchange policy for worry‑free shopping

- One‑year warranty for long‑term reliability

Every starter motor from FridayParts is tested, warrantied, and built for the heavy‑duty demands of off‑road machinery. Shop Starter Motors at FridayParts.com — find the perfect fit for your equipment today and get back to work with confidence.